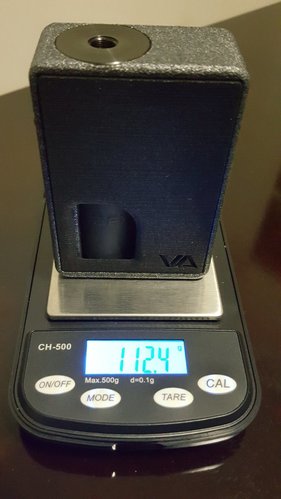

Item for Sale :- Arkon Black Alumide 20700 Squonker with Black 510,Silver Contacts and Black Dome Button.

Selling Price :- R3200.

Condition :- Excellent.No Marks.Spotless

Age of the item :- 2 Months

Clone or Authentic :- Authentic

Location of item :- Centurion

Delivery/Collection :- Delivery on Buyer or can be Collected in Centurion

Reason for sale:- Not being used.

No Trades.Thanks.

Selling Price :- R3200.

Condition :- Excellent.No Marks.Spotless

Age of the item :- 2 Months

Clone or Authentic :- Authentic

Location of item :- Centurion

Delivery/Collection :- Delivery on Buyer or can be Collected in Centurion

Reason for sale:- Not being used.

No Trades.Thanks.

Last edited: