We already discussed how we develop a flavour, but i thought it prudent to dedicate a forum post purely on how Twisp manufactures our flavours.

With every flavour component that we bring in to potentially use in our flavour development we have the flavour concentrate undergo an extensive testing procedure This allows us to identify those flavour concentrates that could have a negative impact on our GMP and potentially be detrimental to our focus on safety for you, the consumer.

All Twisp tobacco flavours are 100% naturally extracted and results in the tobacco flavour in our e-juices, without burning tobacco!

Further assurances in our production process during manufacture include ensuring clean room manufacturing - this is not a photo op, but real working conditions. Clean air only goes so far in assuring a critically manufactured product.

What does our clean room environment entail?

Large volume mixing:

Bottling:

Sealing and checking:

Testing and QC is done on EVERY BATCH

Every batch is accompanied by its own certificate of analysis to ensure that the specs are adhered to and that what you put into your tank is as per our designed formulation and adheres to our safety requirements. This singular step alone establishes not only consistency but also ensures that what we put into our bottles is what you will be consuming while you vape.

Some of our tests include:

A look at our routine quality testing.

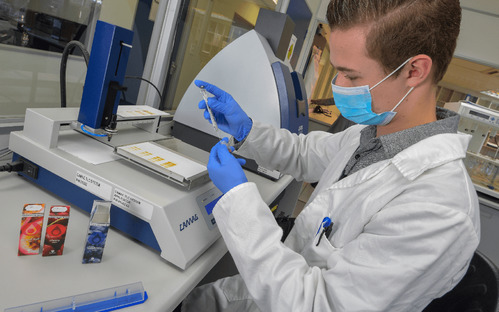

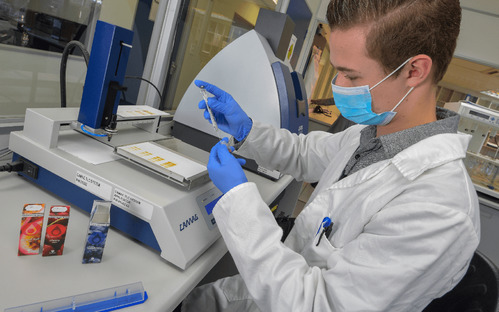

FT-IR IDENTIFICATION:

TLC IDENTIFICATION:

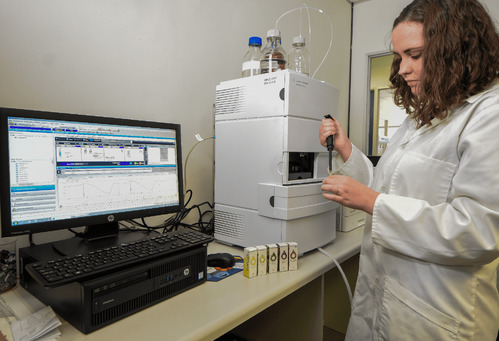

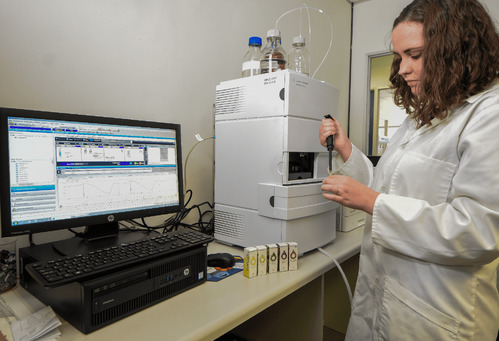

HPLC NICOTINE ASSAY:

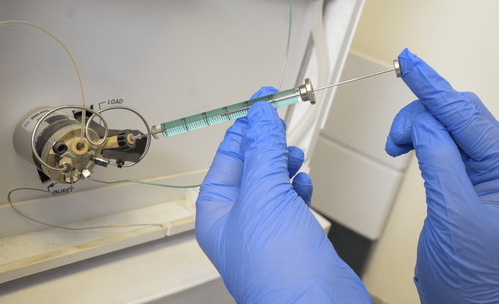

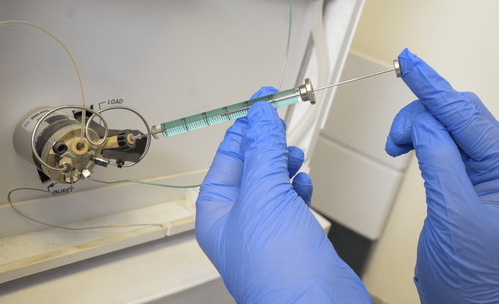

HPLC NICOTINE ASSAY INJECTION INTO HPLC (the syringe in the picture has a blue lining and the clear nicotine sample is in the lighter column in front of the metal plunger)

Ensuring every batch is tested, every process followed to the t is crossed and every "i” is dotted. We stand by our modus operandi and truly believe that Vaping is the safer alternative to smoking. The manufacturing environments and testing procedures are not for bragging rights; it is to ensure that the claim of being a safer alternative can be accounted for.

With every flavour component that we bring in to potentially use in our flavour development we have the flavour concentrate undergo an extensive testing procedure This allows us to identify those flavour concentrates that could have a negative impact on our GMP and potentially be detrimental to our focus on safety for you, the consumer.

All Twisp tobacco flavours are 100% naturally extracted and results in the tobacco flavour in our e-juices, without burning tobacco!

Further assurances in our production process during manufacture include ensuring clean room manufacturing - this is not a photo op, but real working conditions. Clean air only goes so far in assuring a critically manufactured product.

What does our clean room environment entail?

Large volume mixing:

Bottling:

Sealing and checking:

Testing and QC is done on EVERY BATCH

Every batch is accompanied by its own certificate of analysis to ensure that the specs are adhered to and that what you put into your tank is as per our designed formulation and adheres to our safety requirements. This singular step alone establishes not only consistency but also ensures that what we put into our bottles is what you will be consuming while you vape.

Some of our tests include:

- TLC-Identification (ensures consistency of raw materials prior to manufacture)

- FT-IR Identification (ensures consistency between batches)

- HPLC assay (Nicotine content quantification)

- Microbial testing

A look at our routine quality testing.

FT-IR IDENTIFICATION:

TLC IDENTIFICATION:

HPLC NICOTINE ASSAY:

HPLC NICOTINE ASSAY INJECTION INTO HPLC (the syringe in the picture has a blue lining and the clear nicotine sample is in the lighter column in front of the metal plunger)

Ensuring every batch is tested, every process followed to the t is crossed and every "i” is dotted. We stand by our modus operandi and truly believe that Vaping is the safer alternative to smoking. The manufacturing environments and testing procedures are not for bragging rights; it is to ensure that the claim of being a safer alternative can be accounted for.