Busy with the legwork of "designing" my own CNC router and was wondering if anyone has or is doing the same. Will mostly be used for hobby grade wood cutting and maybe making some money on the side to recover the cost in the long run ( so far my costing work out to about R6k for all the parts and then some for building materials. This includes a hacked Ryobi router and not a dedicated spindle )

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: this_feature_currently_requires_accessing_site_using_safari

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Anyone own anything CNC ?

- Thread starter gertvanjoe

- Start date

I did a 3D printer that was a remix of Tech2C's Hypercube off Thingiverse, started from scratch with no printed parts, took 40 days and cost R7300.Busy with the legwork of "designing" my own CNC router and was wondering if anyone has or is doing the same. Will mostly be used for hobby grade wood cutting and maybe making some money on the side to recover the cost in the long run ( so far my costing work out to about R6k for all the parts and then some for building materials. This includes a hacked Ryobi router and not a dedicated spindle )

I took plenty pics to document the build for my Instructables page, https://www.instructables.com/id/Total-Metal-Hypercube-3D-Printer-no-Printed-Parts/

Probably a bit complex for a router which doesn't require a lot of Z axis travel, but it seemed to be the easiest iteration to diy, versus Cartesian, Delta and SCARA styles.

Busy with the legwork of "designing" my own CNC router and was wondering if anyone has or is doing the same. Will mostly be used for hobby grade wood cutting and maybe making some money on the side to recover the cost in the long run ( so far my costing work out to about R6k for all the parts and then some for building materials. This includes a hacked Ryobi router and not a dedicated spindle )

I would love to see your build pics

I did a 3D printer that was a remix of Tech2C's Hypercube off Thingiverse, started from scratch with no printed parts, took 40 days and cost R7300.

I took plenty pics to document the build for my Instructables page, https://www.instructables.com/id/Total-Metal-Hypercube-3D-Printer-no-Printed-Parts/

Probably a bit complex for a router which doesn't require a lot of Z axis travel, but it seemed to be the easiest iteration to diy, versus Cartesian, Delta and SCARA styles.

Nicely done sir

I did a 3D printer that was a remix of Tech2C's Hypercube off Thingiverse, started from scratch with no printed parts, took 40 days and cost R7300.

I took plenty pics to document the build for my Instructables page, https://www.instructables.com/id/Total-Metal-Hypercube-3D-Printer-no-Printed-Parts/

Probably a bit complex for a router which doesn't require a lot of Z axis travel, but it seemed to be the easiest iteration to diy, versus Cartesian, Delta and SCARA styles.

How's the printer doing now?

Mechanically very good, but Im still yet to print consistently & successfully on it, seems like there is 200 items in the firmware and 300 in the slicing software that you have to master and they affect each other.How's the printer doing now?

ie steep learning curve.

Mechanically very good, but Im still yet to print consistently & successfully on it, seems like there is 200 items in the firmware and 300 in the slicing software that you have to master and they affect each other.

ie steep learning curve.

Care to share what problems you are running into ?

Getting the 1st layer right, sometimes it prints about 5mm off the bed in midair, other times it carves grooves in the glue stick layer I use for bed adhesion and then blocks the nozzle.Care to share what problems you are running into ?

Mechanically its fine, homes XYZ fine and even does a nice little ABL "G29" routine without hiccups, but when it moves to bed center to begin the print it starts doing stupid sh1t.

There's quite a few settings in the firmware and slicer software that influence each other, which I'm still learning about.

Getting the 1st layer right, sometimes it prints about 5mm off the bed in midair, other times it carves grooves in the glue stick layer I use for bed adhesion and then blocks the nozzle.

Mechanically its fine, homes XYZ fine and even does a nice little ABL "G29" routine without hiccups, but when it moves to bed center to begin the print it starts doing stupid sh1t.

There's quite a few settings in the firmware and slicer software that influence each other, which I'm still learning about.

Which slicer are you using bud?

I have tried Slic3r v1.2.9, Cura v22 & v25 and an old pirated version of Simplify 3D v3.0.2Which slicer are you using bud?

I prefer Slicr and save to SD card, but got one okay print with Cura on a usb connection and not again.

S3D both via usb and saved on SD was iffy.

I have tried Slic3r v1.2.9, Cura v22 & v25 and an old pirated version of Simplify 3D v3.0.2

I prefer Slicr and save to SD card, but got one okay print with Cura on a usb connection and not again.

S3D both via usb and saved on SD was iffy.

I'm using Cura as well and got some settings off the internet the other day and copied those settings to my Cura and my prints have improved quite a lot. Most of my prints are near perfect now. I'll send you screen shots of my settings. Maybe you can try them out.

Not to hijack the thread on CNC cutters, but that DIY 3D printer is a pretty amazing piece of work! Congrats @blujeenz , great job!I did a 3D printer that was a remix of Tech2C's Hypercube off Thingiverse, started from scratch with no printed parts, took 40 days and cost R7300.

I took plenty pics to document the build for my Instructables page, https://www.instructables.com/id/Total-Metal-Hypercube-3D-Printer-no-Printed-Parts/

Probably a bit complex for a router which doesn't require a lot of Z axis travel, but it seemed to be the easiest iteration to diy, versus Cartesian, Delta and SCARA styles.

Regards

I have tried Slic3r v1.2.9, Cura v22 & v25 and an old pirated version of Simplify 3D v3.0.2

I prefer Slicr and save to SD card, but got one okay print with Cura on a usb connection and not again.

S3D both via usb and saved on SD was iffy.

Just printed this drip tip

Sorry for the crappy photo. I love tapered drip tips and will be buying a micro lathe soon and some delrin rods to turn my own, but this does the job well.

Nice idea, hadnt even thought of drip tips, if you use ABS you could even smooth them out with acetone polishing using the vapour method.Just printed this drip tip

Sorry for the crappy photo. I love tapered drip tips and will be buying a micro lathe soon and some delrin rods to turn my own, but this does the job well.

Nice idea, hadnt even thought of drip tips, if you use ABS you could even smooth them out with acetone polishing using the vapour method.

I would love to have a SLA printer. Those prints are so smooth and perfect, but eish, the price.

Getting the 1st layer right, sometimes it prints about 5mm off the bed in midair, other times it carves grooves in the glue stick layer I use for bed adhesion and then blocks the nozzle.

Mechanically its fine, homes XYZ fine and even does a nice little ABL "G29" routine without hiccups, but when it moves to bed center to begin the print it starts doing stupid sh1t.

There's quite a few settings in the firmware and slicer software that influence each other, which I'm still learning about.

Well i hate to break it to you but its that capacitive sensor. Its pretty crap and is affected by even a mouse fart. I hate them and only use them when i am desperate. Bltouch is the most reliable that i have come across so far. But nothing beats a well calibrated manually levelled bed. I am building a 500x500x500 monster right now and the only reason i am going to use a cap sensor is so that i can print a carriage foe the bltouch before it arrives

Well i hate to break it to you but its that capacitive sensor. Its pretty crap and is affected by even a mouse fart. I hate them and only use them when i am desperate. Bltouch is the most reliable that i have come across so far. But nothing beats a well calibrated manually levelled bed. I am building a 500x500x500 monster right now and the only reason i am going to use a cap sensor is so that i can print a carriage foe the bltouch before it arrives

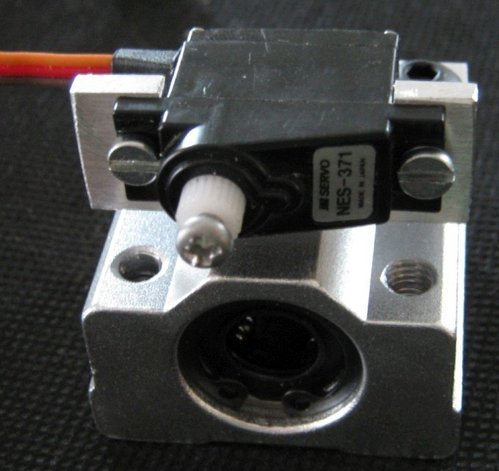

Im using a deployable micro switch on a rc servo.

The glass bed clips tend to distort the glass even though its 4mm thick, which is why I went the ABL route.

The results of a G29 test shows bowing in the middle of the bed.

I am, just not with the cap/ind sensors.Ah ok thought you said you running the hypercube my bad.

I came across ZenmasterM's YT vids on ABL and decided to incorporate that method instead.

Similar threads

- Replies

- 2

- Views

- 919

- Replies

- 5

- Views

- 1K

- Replies

- 3

- Views

- 911