I finally jumped in and built a coil!

I was only planning on re-wicking the standard 0.5 ohm coil that came with the RBA, but after I got the thing open and saw the wire and snips I bought a week ago glaring accusingly at me, I thought I might as well give it a bash!

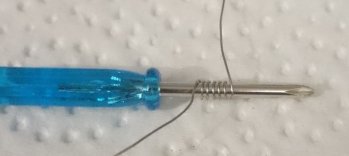

28ga Kanthal

6 spaced Wraps to try and get to 0.8ohm. Inexperience and shoddy workmanship turned it into a 1.0 ohm coil.

The wrapped Coil

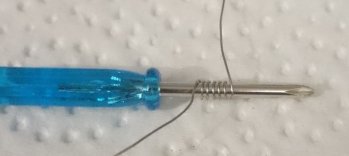

Mounting the coil. More of an hourglass than a cylinder. The spaced wraps meant that I had to try and kink the legs inwards to reach the posts.

I cut myself a wick from some Dove pleated cotton wool - so far, when compared to the cotton I got with the Subtank mini, the only comment I can make is that the Dove cotton pulls apart far easier. Had to be very careful threading the cotton through the coil.

After Threading the cotton through the coil. Had to re-centre it a few times due to cotton just letting go of its neighbours...

Finally got the barrel on and trimmed the wick before shoving the cotton down to cover the holes on the barrel. I tried to pull the cotton through the holes and trim close to the barrel, but the very loose cotton made me rethink this strategy.

I didn't take any pics after this because, frankly, one wicked, juiced subtank looks pretty much like any other to me.

Any tips, tricks, advice and/or scathing criticism are welcome!

I was only planning on re-wicking the standard 0.5 ohm coil that came with the RBA, but after I got the thing open and saw the wire and snips I bought a week ago glaring accusingly at me, I thought I might as well give it a bash!

28ga Kanthal

6 spaced Wraps to try and get to 0.8ohm. Inexperience and shoddy workmanship turned it into a 1.0 ohm coil.

The wrapped Coil

Mounting the coil. More of an hourglass than a cylinder. The spaced wraps meant that I had to try and kink the legs inwards to reach the posts.

I cut myself a wick from some Dove pleated cotton wool - so far, when compared to the cotton I got with the Subtank mini, the only comment I can make is that the Dove cotton pulls apart far easier. Had to be very careful threading the cotton through the coil.

After Threading the cotton through the coil. Had to re-centre it a few times due to cotton just letting go of its neighbours...

Finally got the barrel on and trimmed the wick before shoving the cotton down to cover the holes on the barrel. I tried to pull the cotton through the holes and trim close to the barrel, but the very loose cotton made me rethink this strategy.

I didn't take any pics after this because, frankly, one wicked, juiced subtank looks pretty much like any other to me.

Any tips, tricks, advice and/or scathing criticism are welcome!