Hello everyone!

This is a work-in-progress guide to temperature control (TC) in the vaping domain – what it is exactly, how it works, how it is implemented in different mods, a description of all the variables of TC and how to tweak them in order to modify your vaping experience!

This guide is structured in the following manner:

PART 1. Introduction

1. Factors affecting vaping temperature

2. Temperature control basics: Coil temperature and resistance

3. TC-enabled Mods & Wires, a quick comparison

4. TC variables: Pre-heat punch, power, temperature limit, TCR and TFR

5. Styles of TC vaping

6. Links for more information

PART 2. Fine-tuning your vape

1. Deciding on your TC style, wire material and coil shape

2. Adjusting pre-heat, power and temperature

3. Adjusting linear TCR values

PART 3. Escribe and DNA200

1. What is Evolv, DNA200 and Escribe?

2. Visual tutorial to using Escribe

3. Diagnostics: Atomiser analyser, Device Monitor

4. Modifying TFR values

PART 4: Fixing common TC Problems

At this stage, only Part 1 is fully finished; I will add links to the relative post as I complete them. The old version of this guide was primarily an Escribe guide, and until I’ve finished updating it, it will remain as a separate post linked to Part 3.

I will also be using Escribe & the DNA200 chip to explain and illustrate most of the concepts covered in this guide. However, please realize that the same principles apply to most TC-enabled mods, and most of the capabilities of the DNA200 can be approximated in some way or the other in other chips – it is not necessary to go out and buy an expensive DNA200 mod just in order to apply some of the things covered in this guide. The DNA200 chip was primarily developed as a research tool, and therefore provides a very good diagnostic method to fully understand what is happening with TC vaping, and how to improve on it.

In addition to Escribe, I will be referring a lot to some of the predicted physical properties of a coil, which can be calculated through the excellent vaping calculator, www.steam-engine.org. If you haven’t looked at this website before, now is the time. I will not be going into the details of using this website, but I will be posting a lot of information which can be calculated there.

Lastly, please note that English is not my first language, and, for that matter, my language skills are quite horrible. I also have only a limited knowledge of the physics involved, so if you spot any mistakes, don’t be afraid to point them out! I am primarily a vaper with a tad too much curiosity, so most of what I describe is a result of my own conjectures and therefore should not be accepted as universal truths.

This guide is primarily written for beginners with little foreknowledge of the subject matter. However, I believe that those who have tinkered around with TC might still be able to pick up a thing or two, especially if they themselves have not yet played around with a DNA200 chip. Finally, this guide is written as a generalized overview of TC; unfortunately, not all TC mods work the same, or even use the same terminology - so you might have to use your own discretion to relate some of the information in this guide to your own mod. Alternatively, if you have a question on how the information in this guide relates to your own mod, don’t feel bad to ask about it - somebody somewhere will have the same mod as you and should be able to help!

PART 1. Introduction

1. Factors affecting vaping temperature

So you’ve heard of this temperature control thing. Maybe you’ve taken a toot on a friend’s mod, or your own mod can do TC, but beyond a little bit tinkering, you’ve never bothered to look too closely.

TC vaping is all about measuring and controlling the temperature of your coil as it heats up. What it is not is a direct control of the temperature of the actual vapour which you inhale. Therefore, before jumping into the nuts and bolts of TC vaping, let us discuss first some of the factors which affects the temperature of the final vape product. These factors can be divided into two groups: i) Coil factors and ii) atomizer factors. I will discuss the atomizer factors first:

a) Direct airflow. The amount of airflow you have on the atomizer itself is one of the primary factors of the temperature of your vape. A very large airflow (in other words, large or many holes on the side or bottom of your atomizer), coupled with a strong inhale, will result in a much cooler vape in comparison to the same coil and electrical power in an atomizer with less airflow.

b) Indirect airflow. Many atomizers have indirect airflow holes somewhere not on the coil (such as the drip-tip of the Smok TFV4 - which have controllable airflow at the top). This airflow will always cool the vapour you inhale, since it does not hit the heated coil in any way. It will also disperse the clouds and flavour to some extent - equivalent to keeping the side of your mouth open when vaping. However, it is a great way to cool down an otherwise too hot vape setup.

c) Internal airflow & chamber size. The size of the atomizer’s chamber (in other words, the area where your coil is actually located) have a very big impact on the temperature which you experience. This is in conjunction with the size of your coil, the position of your coil and the amount of cotton you stuff into the chamber. Generally though, larger chambers coupled with smaller coils will give you a cooler vape. However, it is possible to have an atomizer with a small chamber (such as a Goblin Mini or Subtank Mini) coupled with a sufficiently small coil to give a very cool vape. In addition to chamber size, the chamber shape is also important. Here, we have to use our imagination to some extent. The time which the air spends in the chamber is a primary factor of the temperature. If the incoming airflow hits the coil directly, but is blocked either by the size of the coil or the amount of wick, it will spend more time in the chamber and will consequently become hotter. On the other hand, if the incoming airflow only hits the side of the coil, and have a direct path to the chimney, the driptip and the mouth, it will spend considerably less time in the chamber and around the coil and, consequently, be a little bit cooler. In addition, the time which air spends in the chimney (in other words, in the absence of a heated coil) will allow more energy transfer between the air and the atomizer, and again, result in a slightly cooler vape. On aspect which should be mentioned here is the vortex effect. Some atomizers (especially drippers, but newer tanks - such as the Goblin Mini v2 - have this feature as well) have conical or grooved chimneys - which effectively swirls the air around inside the chamber. Usually, this vortex effect results in a slightly cooler vape (since the air spends more time inside the chamber) and slightly improved flavour. This effect works better in some atomizers than others, though.

d) Wicking. I’ve already mentioned that too much wick (especially outside the coil) can block the airflow and result in a hotter vape. Ironically, too little wick can cause the same effect, but for different reasons. This is all about the amount of juice which can be vaporized. Energy is spent by the coil in order to heat the juice - which is an endothermic effect and therefore lowers the temperature. If, however, the coil cannot effectively vaporize the juice and the excess heat of the coil is transferred to the air around it, as well as the atomizer, and results in a much hotter vape. When vapers complain that their atomizer (and vape) becomes very hot but without large clouds and/or flavour, this is usually the problem.

e) Heat capacity of the juice. The content of different juices heats up at a different rate, depending on the PG/VG ratio, the amount and composition of flavours and the nicotine concentration. This is determined by the partial heat capacity of each component – in other words, how much energy is absorbed by each component in order to raise the temperature (and eventually vaporize) of that component. High heat capacities leads to more energy required to vaporize it, and generally (for the same power) results in a cooler vape. This effect should be noticeable by many vapers - when you change the juice of a tank/dripper but nothing else and you suddenly get a warmer/cooler vape. I haven’t hunted down the exact heat capacities for each component, but I will probably do so in the near future for the sake of Science!

Next, and before we discuss the relevance of these factors with regards to TC, we will quickly discuss the coil properties and their influence on the final vaping temperature:

a) Power. The actual number and velocity of electrons (the current and potential difference, respectively, coupled with the resistance) flowing through the coil will obviously influence the heat of the coil the most. Higher power (in watts) will result in either more electrons or faster electrons moving through the coil, which results in more collisions through the coil, which results in higher energy and, finally, a higher temperature.

b) Coil resistance. The coil resistance is often misunderstood by many vapers. The resistance of a wire is what causes the actual energy increase when electricity is passed through it. However, a lower resistance will allow more electrons to be passed through the coil at a quicker rate (effectively, with more force), which actually results in a larger number of collisions between electrons and metal, which actually results in higher energy and temperature increase in the coil. This is more apparent when a mech mod is used, which has the same voltage in different coils, but because of a lower resistance in one coil, will result in a larger current draw, larger power and finally, higher temperature. With regulated mods, things change a bit, since the mod determines the voltage needed to reach a specified power with a given coil resistance. Generally, however, even in a regulated mod vapers testify that lower coil resistances gives more clouds at the same power output. The bottom line is that higher resistance coils will generally heat up quicker, but will hit a more or less max temperature than lower resistance (but slower heating) coils.

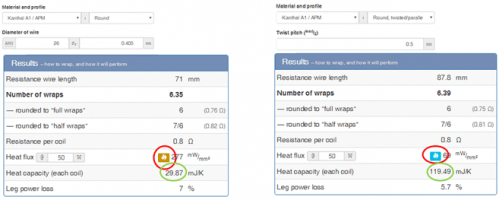

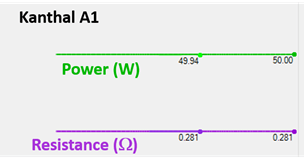

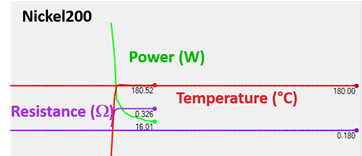

c) Heat flux and surface area. Here, we will ask the assistance of the wonderful www.steam-engine.org, which can calculate a predicted heat flux and surface area of a coil. The heat flux of a coil gives the power distribution per mm2 surface area, and is an indication of the amount of power needed to heat up a coil. A coil with a lower heat flux will therefore require much more power to heat up to the same temperature than a coil with a higher heat flux. Consequently, the heat of the coil (which is more or less correlated with the heat of the vape) with a low heat flux will be much lower at the same power than a coil with a higher heat flux. The heat flux is directly correlated with the surface area of the coil - a larger surface area will result in a lower heat flux. On the other hand, a larger surface area allows for more juice to be vaporized at the same time, as well as more air to pass over the saturated coil - which therefore results in more flavour and vapour. The result is that a coil with a lower heat flux can be vaped at higher power for the same coil temperature, which generally results in more flavour and larger clouds (if the airflow is sufficient). Steam-Engine actually has a very nice, qualitative feature which tells you how hot the vapour will be at a given power output.

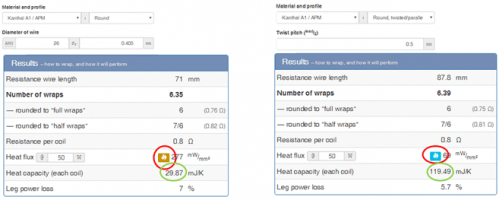

In the above example (taken from Steam-engine), you can see that the coil on the left (a dual coil Kanthal 26 AWG) has a very high Heat flux of 277 mW/mm2 at 50 W, and steam-engine predicts that it will be quite a hot vape. On the other hand, the same general coil, only twisted, will have a much lower heat flux (69 mW/mm2 @ 50 W) and will be much cooler at the same power, as indicated by the little blue icon.

d) Heat capacity. Another property calculated by www.steam-engine.org, the heat capacity determines how much energy (directly related to power) is required to raise the temperature of the coil by 1 degree Kelvin. The heat capacity gives the ramp-up of a coil - in other words, the time required to heat up a coil at a given power output. Higher heat capacity results in a lagging coil (typical for Clapton coils) which will take some time to get to a decent vaping output.

In the example above, the non-twisted coil has a low heat capacity of 29.87 mJ/K (milli Joules per Kelvin - or energy per degree temperature), and will therefore heat up very quickly. The twisted coil, on the other hand, has a heat capacity of 119.49 mJ/K -about 4 times higher. This coil, despite being much cooler at higher wattages (as given by the heat flux), will take much longer to heat up due to the high heat capacity.

Lastly, the ambient temperature plays a very big effect in the temperature of your vape. Even though most TC mods can compensate for the ambient temperature of the wire, the temperature of the air going into your atomizer will determine a large amount of the final vape temperature. In other words, your atomizer and vape will generally heat up much faster on a hot day than a cold one.

The bottom line of this lengthy discussion is that the temperature of your vape is a result of many, interplaying factors. The biggest of these is the power given to the coil and the available airflow (both in terms of direct airflow and the size/shape of the coil inside). The take-away is that, even though we call TC vaping temperature controlled, TC really refers only to coil-temperature controlled. Your TC mod might read 250 °C, but the actual vapour temperature will definitely not be 250 °C, and what’s more, it will feel very different in different atomizers (or in the same atomizer but with different coil setups). I’ve actually once tried to calibrate all my atomizers to give the same perceived temperature for the same TC temp, but that turned out to be too big of a schlep. It is important to realize that while with TC vaping you can control to some extent the temperature of your vape, the biggest factor in the final temperature of your vape will still be determined when you build the coil or select an atomizer.

2. Why TC?

If the temperature of your inhaled vape is a result of many factors, why would anyone bother with TC then?

In the most elementary implementation, TC will give an upper limit to the temperature of the coil and prevent dry hits. This is nice for drippers, as you can continue vaping until your coils are effectively dry without having to experience increasingly dry hits. It is also nice for tanks, especially if the tank isn’t wicking wonderfully, and you can finish a tank completely before refilling with a new juice. In this implementation, you can also take longer and more consecutive draws of your atomizer without having to risk a dry hit.

However, TC can be used to better optimize your vape to suit your style. In normal non-TC power (or Kanthal) vaping, the only variables left for your control (after you’ve built your coils) are the power output and airflow control. TC adds a few additional variables which can be tinkered with in order to fine-tune your vape. On the one hand, it can be used to control coil builds which ramps up too quickly, in order to take longer draws at the desired vape temperature. It can also be used to control builds which ramps up too slowly, in order to reach the desired temperature as soon as possible. TC is especially useful for juice tasting, and especially for vaping complex juices which get the best distribution of flavours at a specific temperature, or if a specific juice has an undesired note at higher temperatures.

However, none-TC builds are still more user friendly in terms of pick-up-and-vape. TC really asks for some tinkering, playing around and curiosity towards your setup. You can use this guide to set your TC up in such a way as to just prevent dry hits or vape at a specific temperature, but you can also use this guide (in conjunction with some dedicated tinkering time) to really get a great vaping experience!

3. Temperature control basics: Coil temperature and resistance

TC is in principle a method rooted in calibration. A TC mod approximates the temperature of your coils, and adjusts the power output dynamically as needed: if the coil temperature reaches a maximum, the power is reduced accordingly in order to keep the temperature from rising further. If the coil temperature is too low, the power output is increased. The amount of control a mod has over the power output is dependent on how accurately it can measure the coil temperature, and how finely it can adjust the power output. Earlier and less advanced TC mods tends to have less finer control over the power output - once the coil temperature hits a limit, it drops the power too much and a noticeable drop in vapour production can immediately be experienced. More advanced TC mods, on the other hand, adjusts the power accordingly before the temperature limit has even been reached, and can minutely adjust the power in order to keep the coil temperature constant. The same applies for accuracy, which is generally more a factor of the coil material. Certain materials’ (such as Nickel) temperature can be approximated more accurately, which means the corresponding power adjustments can be improved to keep up with the changing temperature.

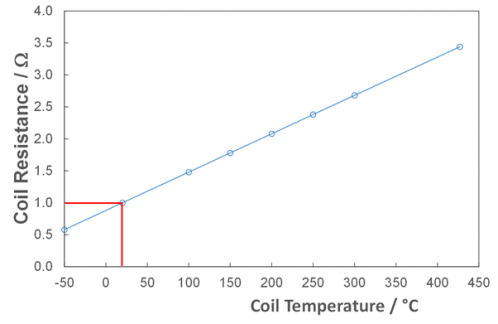

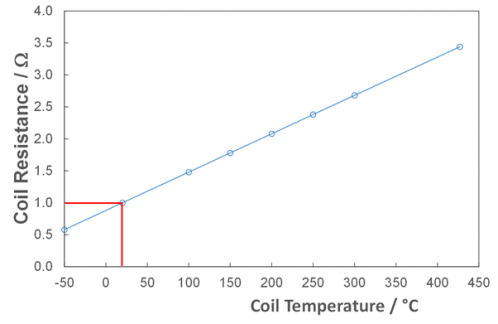

The biggest caveat to all of this is the fact that the coil temperature cannot be measured directly - a mod does not actually have a thermostat (or any advanced instrument for analysis) directly connected to the wire in order to measure the coil’s temperature. However, all metallic wires have a very useful intrinsic physical property: a coil’s resistance increases as it gets hot. Using this property, a relationship between temperature and resistance can be established. In other words, a mod only has to measure the change in the resistance of a coil (which even none-TC regulated mods do anyway), and through a mathematical relationship, it can estimate the temperature of the coil.

The relationship between temperature and resistance can be modelled in different (and generally of different levels of mathematical complexity) ways. The most basic way is linearly (in other words, through a single value) and is known as the Temperature Coefficient of Resistance (TCR). The TCR gives how many degrees of heat (which can be given in Kelvin, Celcius or Fahrenheit) a wire increases for each increment of change in resistance (in ohms). Each material has a specific TCR, and it doesn’t matter whether you have a single coil, a twisted coil or a clapton coil - the TCR remains the same. We use the same TCR for dual/tri/quad coils as well, although there is a bit of a debate regarding the accuracy of doing so.

To simplify things, lets take an example. Lets say we have a stainless steel (specifically, SS 316L - a specific stainless steel alloy) coil with a resistance of 0.50 Ohm at room temperature (RT). We then fire our mod for 2 seconds at 30 Watts, and we see the resistance of the coil jumps to 0.55 Ohm. When we stop firing the mod, it cools down (very slowly) until it reaches 0.50 Ohm again.

Stainless Steel (SS-316L) has a TCR value of 879 x 10-6 Ohm/°C, or 0.000879 ohms per change in degree Celcius (scaled to a 1 Ohm coil).

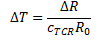

The equation for calculating the temperature change from a resistance change (given in °C) is this:

where DT and DR gives the change in temperature and resistance, respectively (in other words, the final temperature or resistance minus the initial temperature or resistance), cTCR is the TCR constant (specific to the material type) and R0 is the resistance of the coil at RT. The TCR is defined for a wire with 1 Ohm, which is why it is scaled in the denominator of the right-hand side of the above equation by the initial (cold) resistance of the coil.

When our coil changes from 0.50 Ohm to 0.55 Ohm, the change in resistance, DR = +0.05 Ohm. We can get the change in temperature by plugging into the above equation (or, in other words, by taking DR = +0.05 Ohm and dividing by the TCR times the initial resistance (0.50 Ohm))

(0.55 – 0.5) / (0.000879 * 0.5) = 113.77 °C. In other words, our coil changed from RT (lets assume 25 °C) to (113.77 + 25) 138.77 °C.

The TCR therefore gives us how large the change in resistance will be for a change in one °C. For SS 316L, each °C increase from RT will give a 0.000879 Ohm change in resistance, for a 1 Ohm coil. For a 0.5 Ohm coil, the change in resistance for each 1 °C will be (0.000879 * 0.5) 0.00044 Ohm; for a 2 Ohm coil, it will be (0.000879 * 2.0) 0.001758 Ohm.

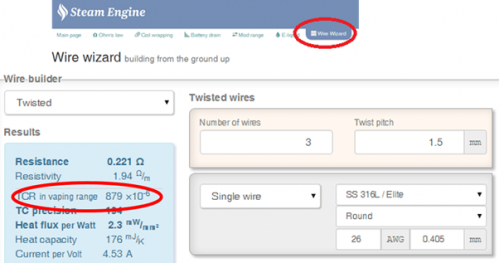

The higher the TCR value, the larger the change in resistance. For instance, Ni200 (a primarily Nickel alloy) has a TCR value of 0.006 -almost an order of magnitude larger than that of SS316L. Therefore, each 1 °C change in temperature of a 1 Ohm Ni coil will give a 0.006 increase in resistance.

On the other hand, lower TC values will give a much smaller change in resistance. In fact, Kanthal A1 has a TCR of 0.000002 - in other words, each 1 °C change in temperature will increase the resistance of a 1 Ohm coil by only 0.000002 Ohm. This is the reason Kanthal cannot be used for TC - a change of 280 °C temperature (roughly when your cotton will start to burn) will give a change of 0.00056 Ohm. A 0.5 Ohm coil will therefore still be measured as a 0.5 Ohm coil on even the most accurate Ohm-meter - and therefore, no mod available can detect any significant change in the resistance of Kanthal.

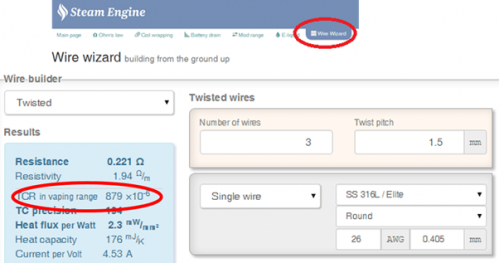

Practically speaking, most vapers don’t have to worry about the specifics of the TCR at all. Most mods have a default TCR value built in for each material type (and therefore, when you select your material, the mods selects an appropriate TCR value). Some mods have an additional feature where you can specify a TCR value, such as the Evic-VTC mini/Cuboid or the RX200. If you want to use this mode, you have to check the correct input value. For instance, the Smok X-Cube 2 can read user TCR values, and it reads it exactly - in other words, the TCR value for SS316L will be read as 0.000879. On the other hand, the Evic-VTC mini reads the TCR value as 105. So the 0.006 TCR value of Ni200 should be inputted as 600 on the VTC mini.

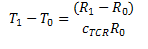

Generally, if you need a TCR value for a specific wire type, you can get them easily on the net. My favourite way of getting these values are from www.steam-engine.org, in the Wire Wizard tab. Just change the material to your wire type - you don’t even have to change the wire gauge, or coil dimensions - the TCR will remain the same. Then you can just read the TCR value from the tab on the left.

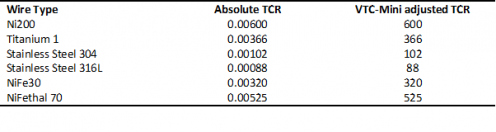

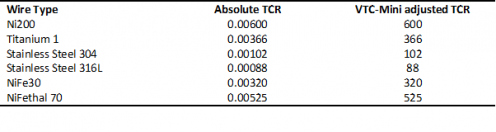

Here is a few TCR values for common wire types:

Note that Ni200 has the highest TCR of the lot - which means that the resistance increase for each 1 °C is larger than any other wire type. SS316L, on the other hand, is almost 10 times lower than Ni200. More on that a bit later, in the next section.

Unfortunately, the specific alloys, as well as production procedure, for each wire type differs quite a bit between different manufacturers. This means that, unless that manufacturer included the TCR for their specific wire type, the TCR which you get from the web might not be the actual TCR of the wire. Usually, this isn’t a problem, as the accuracy for Ni200 and Ti are usually good enough to account for any small changes in the wire TCR, but it can sometimes be an issue with SS wire. Luckily, there are a lot of people on the web who have bought from the same manufacturer as you did, and someone somewhere has a modified (usually better) TCR value which you can use. In a later part of this guide, I will go over what adjustments are necessary for fine-tuning your TCR, but for now, you can use this rule of thumb:

Larger TCR values will give a hotter vape, whereas smaller TCR values will give a cooler vape, for the same temperature value.

If you do adjust your TCR, make adjustments on the fourth or fifth decimal. If you increase your TCR, just watch out as you might run a risk in increasing it too much - which means you can set your wick ablaze when the mod thinks you are only at 200 °C.

The bottom line, and most basic principle of TC, is that your mod can read changes in the resistance of a coil, and relate that to the coil temperature. In principle, this is just a calibration - the temperature value itself does not relate directly to the temperature you inhale, nor does it necessarily relate to the temperature of the wire. Your TC capabilities on your mod therefore comes down to how accurately the resistance changes can be measured, and how well the resistance changes are calibrated to temperature changes.

4. TC-enabled Mods & Wires, a quick comparison

I unfortunately don’t own a large collection of mods, and have not yet had the luxury of vaping on many different ones. However, I will first discuss the basic differences in technology of the different branches of TC mods.

The most basic (and original) TC mods could measure the resistance of a wire, calibrate it with the TCR for Ni200, and calculate a change in temperature. When the temperature hits a pre-defined limit (usually 290 to 300 °C - the flash-point of cotton), the power to the mod would cut out for a short period of time (usually between 0.1 and 0.5 seconds), before starting up again. In this way, your vape would cycle between high power and no power, but you would be guaranteed to never get a dry hit. These original mods only worked with Ni200 wires, although you could use other TC wires by adjusting the temperature limit accordingly (higher for Ti, even higher for SS).

Newer class mods improved on the original design by including pre-set TCR values for different wires, and improved on how the power was adjusted when a limit is reached: instead of cutting out completely, these mods would reduce the power somewhat in order to keep the temperature constant. Some did it still in increments (reducing the power by 40% for 0.5 seconds at a time), whereas some tried to measure how close the resistance is fluctuating around the temp limit, and tried to gauge how much power needed to be reduced.

More advanced mods allows the user to enter custom TCR values, or adjust the TCR value of certain wires by some amount. Newer mods also still improve in the power-reduction handling, as well as including features such as ramp-up or preheat (more in the next section) in order to reach the temperature limit as quickly as possible. In addition, newer mods occasionally have ambient temperature sensors, which helps to adjust the initial (cold) temperature of the wire. Newer mods also tend to have more accurate resistance sensors.

Finally, the most advanced mods on the market (generally mods with the DNA200 chip, or the new YiHi SX-class chip) don’t just use TCR values anymore, but have a TFR curve (again, more in a later part) which effectively has different TCR values for different temperature ranges, making the entire temp-resistance curve non-linear. These mods also can integrate with computers for more customized setups, diagnostics (real-time measuring) and research.

Generally though, you don’t need the best TC mod in order to get a good TC experience. The computer-integrated chips are wonderful for tinkering, but not necessary. Even old mods (which can only run in Ni mode) can be ‘fooled’ with other wire types by adjusting the temperature accordingly (more on this in a later part!) However, newer mods tend to run more difficult wire (such as Stainless Steel, or complex twisted/claptonned builds) considerably better.

The wire type makes a big difference to the final experience though. Different wire materials differ in their ease-of-build, TC accuracy, base resistance, taste, danger, the ability to run in power (non-TC) mode and build capabilities. I only have experience in Ni, Ti and SS, so I will not cover other types of TC wires (such as NiFe, or NiFethal).

Nickel. Nickel is the original TC wire. It has quite low basic resistivity (0.75 Ohms per meter for a 26 AWG Ni wire, which will give 0.056 Ohm on a single 8-wrap 2mm ID coil), and therefore Ni coils will almost always be very low in resistance. For this reason you won’t often see commercial Ni coils other than single coils, and usually with many wraps. Because of the low resistance, you will almost always see Ni coils changing in resistance quite a bit during the initial few vapes, before it settles. Nickel is also a pain to work with - it is very soft, and therefore it is very easy to deform a coil when installing it. Finally, Ni can form oxides at higher temperatures (usually NiO2), which are extremely toxic when inhaled. For this reason, Nickel should not / cannot ever be used in non-TC (power) mode, when the temperature of the coil isn’t controlled, since it can very easily reach a high enough temperature to form toxic oxides. For the same reason, you cannot pulse your Ni coils when building them, as they might form an oxide layer just by pulsing (when they are not covered in juice). Therefore, Ni coils will almost always be built as spaced coils, which generally does not need pulsing to remove hot-spots and to get the coil ready. If you are building Ni coils, do so with moderate spacing, and do not under any circumstances fire your mod before they’re wicked and juiced, and do not ever run it in a non-TC mod or in non-TC mode.

However, if you work with it cautiously, Ni works wonderfully. When Ni is run in TC mode, the temperature will never reach anything high enough to start forming toxic byproducts (in fact, when a chemical reaction starts to take place on the coil, such as oxide formation, a large spike in resistance will occur and will be measured by the mod, after which the temperature will be immediately controlled). Ni has a very clean taste, and because of its low ohms and low heat capacity, does not require a lot of power to get hot very quickly. Finally, Ni has a very high TCR value - which means that very large resistance changes are observed for each 1 °C increase in temperature. Mods can therefore measure the change in resistance very accurately, and, correspondingly, determine the temperature correctly. The result is a very clean and absolutely temperature controlled, smooth vape, with almost undetectable changes in power, which more than makes up for the difficulty in building with it. In addition, because of Ni’s high TCR, it is very nice to include a single Ni strand through a complex Kanthal build (such as including Ni in a Clapton’s core, or twisting Ni with other wires) in order to add TC capability in an otherwise power-only build.

Some people are sensitive to Ni though - so if you don’t know whether you are sensitive to it, give Ni a toot or two and if you feel any scratchiness, throat/lung contractions or heavy breathing, then sell your remaining spool and never bother with it again.

Titanium. Titanium is a compromise between Nickel and Kanthal. It has a much higher base resistance (3.65 Ohm per meter for a 26 AWG Ti wire, which will give 0.276 Ohm on a single 8-wrap 2 mm ID coil) but still quite low in comparison to Kanthal builds. Therefore, when building with Ti, expect a low resistance, but generally it will never be too low for a mod to fire on, and it is easier to do dual/tri/quad Ti without too much issues than with Ni. Ti does have a bit of a more metallic taste (occasionally - I’ve never been able to pick it up) but for whatever reason, I enjoy Ti vapes immensely in terms of taste. Titanium is also very hard, springy wire, which is a double edged sword. On the one hand, once you’ve built a coil with Ti, it remains that way. You can install the coil without deforming it whatsoever, you can push very thick wick through it without deformation, etc. I actually love building vertical Ti builds, since verticals are occasionally difficult to wick with a deformation risk. On the other hand, because of its hardness, you’ll have trouble doing parallel coils with it, or combining it with other wires - it becomes very, very difficult. That said, I love Titanium. It has a TCR value roughly half of Ni’s, which means it is not as accurate, but I’ve generally found that it still falls well within the accuracy of most TC mods. Ti will also form oxides (again, predominantly TiO2 and TiO), which are toxic, but it happens at a higher temperature than Ni. As a result, I would still strongly recommend anybody to never vape Ti in non-TC/power mode, buuuut.... you can pulse Ti very slightly when building. Do so at very low watts (5-15 W) and make sure that the coils never start glowing brightly. In this manner, you can build compressed Ti coils, as well as tweak that hard-mofo before you wick it, as long as you are careful. Just watch out that a white powder residue never forms on your coils - these are signs of Ti-oxides, and if that happens, remove and dispose of the coil.

Generally, Ti is my favourite wire by far. It has enough TC accuracy to give a smooth vape, high enough resistance to build to your hearts content, good hardness to allow some errors during wicking/installing without needing to throw the coil away. On the other hand, it cannot be run in power mode, it is difficult to build more advanced coils with, and I’ve noticed it tends to gunk relatively quickly - it doesn’t have a tremendously long lifetime, and my coils generally only survives one rewicking before I need to rebuild.

Stainless steel (specifically, SS-316L). Stainless steel is the (relatively) new-comer on the block. It is quite fascinating wire. It has a still-higher resistivity than Ni or Ti (5.82 Ohm per meter for 26 AWG, giving 0.441 Ohm for a 8-wrap, 2 mm ID single coil), which means you can actually use lower guage SS to great effect, as well as play around with parallel/complex builds without having to worry about too low ohms. It is quite soft wire (softer than Kanthal and Ti), but not as annoyingly soft as Nickel. The best thing about stainless steel is that it can be used in TC as well as non-TC mode - Stainless Steel needs massively high temperatures before thermal oxidation will start to occur. That means you can generally build coils like you’d do with Kanthal, including pulsing your coils. It also means that you can have an atty with SS coils and transfer the atty from TC to non-TC mod without issues, or switch to power mode if you messed up with the TC configuration somewhere. Many vapers also report that SS has a very clean taste - with very little to none ‘metal’ taste. (My own tastebuds honestly can’t tell a difference between any of the wires). I also don’t know of anybody who are particularly sensitive to stainless steel, so generally none of those worries either. Stainless steel does have a slight tendency to melt when pulsed to high (specifically where the legs are screwed down), but that generally only happens if you tend to shout YOLO while you build. In the same vein, SS will be easier cut than Kanthal or Titanium if you have sharpish screws in your deck.

SS does have a few issues when it comes to TC, however. Firstly, and most importantly, it has a very low TCR value - which means that SS coil resistances changes very little when heated in comparison to Nickel (~ 10 times less) or Titanium (~ 5 times less). These smaller changes in resistance becomes more difficult for your mod to read, which means its TC accuracy is quite low. Practically speaking, you might often encounter a very observable drop, or fluctuation, in your vape when it nears the temp limit. With tweaking (either of your TCR or TFR if you have escribe) you can alleviate these effects somewhat, but it generally is (for me at least) never as good as Ni or Ti. Secondly, as I’ve already mentioned, the quality and physical properties of SS wires differs greatly from alloy to alloy and manufacturer to manufacturer - which means that SS often times requires more initial playing around with the TC settings to get right. Lastly, because of the low TCR, you cannot generally use SS as a ‘temp-sensing’ wire in more complicated builds, and mixed with other TC wires it generally just messes up your TC.

On the other hand, with SS you can build more complicated builds (such as all-SS clapton, or all-SS twisted) wires much more easily and efficiently, and still have these builds working in TC mode. I enjoy SS quite a lot, and have found that some of the TC issues can be sorted out through playing with the TC settings and building higher resistance coils. Since the change in resistance observed when heating a coil is larger for higher resistance coils, you can significantly improve SS TC accuracy by building higher resistance coils than what you would build with Ni or Ti.

In summary, despite the large number of mods out there (and their respective price differences), you generally want a slightly newer mod which can at least: i) read custom TCR values ( or at least handle different wire types), ii) adjust pre-heat/punch, wattage limit as well as temperature limit and iii) support firmware upgrades. The last point is probably the most important, since if you have a mod which can be upgraded, you are generally much more future proof (for new developments in TC technology and wires) and won’t necessarily need a newer mod in the future.

In terms of wires, I would suggest starting with SS. It is easy to work with and it can run in power mode if you mess up (or don’t like) the TC setup. Ti and Ni have their separate issues (including health issues), so stay away from these wires until you have read more on them and know what you are doing. My personal favourite is Titanium, but it requires a little bit caution to work with initially, and therefore is not recommended for beginners. I never build Nickel coils, unless I use a single strand of Ni in a more complicated build as a temp-sensing wire (although I usually try first with Ti).

5. TC variables: Pre-heat punch, power, temperature limit, cold-resistance and resistance-locking, TCR and TFR

When you vape in normal, non-TC power mode, once you’ve built your coils your only real variables for altering your vape is i) changing the power (watts) and ii) opening/closing your airflow (if you have an atomizer with airflow control). This is generally build-and-vape - you don’t generally have to play around with your mod in order to get a good vape.

TC, on the other hand, adds a number of additional variables which you can use to tune your vape. I will be discussing these variables in terms of a DNA200, which has the most clear definition and realization of these variables. Therefore, your mod might not have all of these variables (or it might have more), or it calls these variables by a different name. If you are unsure of how these terms reflect to your own mod, don’t be afraid to ask!

Temp Limit: The basic variable of TC is locking in an upper temperature limit. This limit is usually given in Fahrenheit or Celsius (most mods can do both), and is in the range of ~150 to 300 °C. When your coil temperature nears, reaches or crosses the temperature limit, your mod reduces the power given to the coil. Very simple, right? In the most basic sense, your temperature limit will prevent your coil from burning (which is in the range of 290 to 310 °C, for cotton generally saturated with juice, or around 270 to 290 °C for a bone-dry coil). If your TC setup is accurate enough (in terms of mod, wire and build) then you will have the same temperature on your coil for the duration of your vape. In comparison, running in power mode, you will generally increase your temperature the longer your drag lasts. Therefore, your temperature limit is a great way of limiting your vape output (in terms of clouds and flavour) without having to worry about how long you drag. This is actually very useful for MTL or restricted lung hits, which tends to be longer drags.

Initial setup: Use a high temperature (~250 to 270 °C) to prevent dry hits, allowing you the same type of vape you would use in power mode just with added protection.

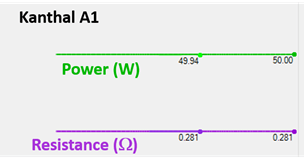

Power Limit: Most TC mods allow you to set a power limit (usually just called power) in addition to a temp limit. The power limit is what your mod will attempt to fire until your coil reaches the temperature limit. In other words, if you have a power limit of 50 watt and a temp limit of 220 °C, your mod will fire at 50 Watt, with increasing temperature, until the coil reaches 220 °C, after which the temperature will remain constant but your power will drop below 50 Watt. If your temperature starts dropping again, most mods will try to return to 50 Watt (but no higher) until the temp limit is reached again.

If your power limit is too high (such as max power of 50 or 75 watt on single battery mods, or 120/180/200 watts on multiple battery mods), you will often experience a ‘pop’ when you hit the fire button. This is because the mod hits with a massive power before it can read the temperature of the coil, and only after a split-second will it be able to reduce the power in order to match your temperature. In a worst-case scenario, you can blow your coil instantly, and you would need to rebuild/buy a new coil, as well as running risk of your wick catching fire or getting a large payload of super heated juice. Best case scenario will net you an initial large puff of vapour, followed by almost nothing (since your mod overcompensated the large spike in temperature). Many people will tell you to set your power limit very high and only worry about your temp limit. This is generally a very incorrect way of thinking, and can lead to pain, suffering, the dark side and galactic tyranny and all that jazz. Your power limit, in conjunction with your temp limit, are your most useful tools in TC and just these two variables alone can be used to give you a great vaping experience - so please don’t arbitarily forget about your power limit when running in TC!

Note, some mods call a power limit an ‘energy limit’ or ‘Joules’ - referring to the effective heat differential experienced at the coil. It comes down to the same thing though - using power (watts) is just more intuitive, in my opinion.

Initial setup: Use the same general wattage you would use in power mode, with a high temperature, to prevent dry hits but otherwise keep your style of vaping the same. Alternatively, put your wattage a bit higher than usual, but reduce your temp limit.

Pre-heat power/time/hardness: Pre-heating, or ‘punch’, is a feature of newer TC mods. Your mod hits with a higher power than the power limit when you just hit the fire button, before it returns to the normal power limit (or, if during the pre-heat the coil has reached the temp limit, it goes to lower wattages). Usually, the pre-heat lasts for a specified number of seconds (pre-heat time), or it lasts until the temperature limit has been reached (pre-heat hardness). The hardness is usually some scale (such as the idiotic 1-11 scale of the DNA200, or terms such as soft, normal or hard) which relates to how close to the temp limit the coil temperature has to reach before the pre-heat stops. In other words, a hard pre-heat will give more power until the coil temperature reaches the temp limit, whereas a soft pre-heat will give more power until the coil temperature reaches a fraction (such as half, or three-quarters) of the temp limit. As an example, lets say you have a temp limit of 220 °C, a power limit of 50 watt, a pre-heat punch of 80 watt, a pre-heat time of 2 seconds and a pre-heat hardness of 6 (normal, or three-quarters hardness). When you hit the fire button, your mod will pump out 80 watts. This will last for 2 seconds, or if your coil temperature reaches 165 °C (three quarters of 220 °C). Then, your mod will drop to 50 watts (your power limit), and will continue to pump 50 W until your coil temperature reaches 220 °C, after which it will drop to lower watts in order to keep the temperature constant.

The pre-heat is therefore a very useful variable in order to heat up your coil to a desired temperature. If you want a strictly constant temperature for the entire duration of your vape (from start to end), then keep your pre-heat power high, pre-heat time long and hardness high. Alternatively, you can play around with a combination of pre-heat, power limit and temp limit in order to have a bit more of a dynamic vape. This is covered more in the next section.

Some mods don’t have a power limit, but just a hardness scale (eg, most SMOK mods, such as the Koopor or the X-Cubes) - in terms of soft, normal and hard (and everything in between). This is generally a pre-defined power limit, and relates to what fraction of the temperature limit is needed before the wattage drops.

Cold or Nominal Resistance, and resistance locking: Since TC measures the change in resistance, it is very important to have a baseline resistance for the mod to use as a calibration of the temperature curve. For almost all TC mods, this baseline resistance is known as the cold resistance, and is usually defined as the resistance of your coil at room temperature (which is not, for whatever reason, 25 °C but more often 20 °C. Stupid North-centric thinking...). The nominal resistance of your coil is the resistance of your coil at the current ambient temperature - but generally not something that you have to worry about. You don’t have to cool your atty down to 20 °C when you connect it (unless you have a fancy mod with an ambient temperature sensor, such as a DNA200 - in this case, you will have an absolutely consistent TC curve if you can connect it at around 20 °C), but you have to make sure that your atty is cooled down entirely.

It is extremely important that when you attach an atty to your mod that the atty is cooled down to the current ambient temperature. Just to give you an indication of the sensitivity we are talking about, consider the following example. You have an SS coil installed, with a resistance of 0.5 Ohm, at the current ambient temperature of 28 °C (your mod will most likely assume it at 20 °C, but the 8 ° difference won’t hurt us much). You take a toot or two on it - and the coil temperature jumps to 240 °C, with a resistance of 0.68 Ohm. If you remove and reconnect your atty (and stating that it is a ‘new coil’ - more on this in the next paragraph), your mod will think the base resistance is 0.68 Ohm at 20 °C. If you hit it now, it will go up to what the mod thinks is 220 °C, but the resistance will be 0.86 Ohm, which in reality will be ~400 °C. In other words, you will get one hell of a dry hit, and most likely some fire from the atty as well. This is a drastic example, but take my word that even a change of 0.05 Ohm of the base resistance can lead to very large (40 to 100 °C) changes in the measured temperature in comparison to the actual temperature. This will either lead to a dry hit when the mod thinks it is still safe, or practically no vapour at all.

Your mod determines the cold resistance when you connect an atty - it assumes the atty is sufficiently cooled down. However, this is not always practical - maybe you have an atty that you have to remove in order to refill, but don’t want to wait 10 minutes before you reconnect it. For this reason, almost all TC mods have a check when you connect an atty. It will generally ask you “Is this a new coil? Y or N?” prompted by a left or right button press. If you say “no” it will use the previously determined last cold resistance which it used. If you say “yes” it will read the resistance of the atty, and use that value as the cold resistance. Note that most mods have an undocumented function where you can reset the cold resistance (or at least reset the prompt) by disconnecting your atty, then hitting the fire button (with no atty connected). Doing so will result in your mod always asking whether your coil is new when you reconnect it.

Lastly, if your atty does not sit flush on the 510 or other connector, or if you’re wire installation is a little bit wonky (doesn’t always connect perfectly) your resistance (as measured by the mod) might fluctuate a bit (generally on at least the second decimal). This is usually not a problem for most atomizer/mod combos, but if it is, most mods have an option to “lock” the resistance. The procedure is generally the same - once you’ve connected an atty and the cold resistance have been determined, you can lock the cold resistance (usually through the mod’s menu, or a sequence of button pushes - check you manual). If the cold resistance is locked, then that is the resistance used as the base resistance for calculating resistance changes, regardless of the actual resistance of the coil. In this manner, you can get the same consistent vape at a given temperature even though your atty might read a little bit different every time you connect it. The pitfall though, is that if the actual cold resistance of your atty changes at some time (due to temperature fluctations, or coil/wick settling) then you might discover that whereas 200 °C was a pleasant vape an hour ago, now it is a burning pit of molten Bronuts.

Locking your resistance is a bit of a disputed issue. Some people say you say that you should always lock your resistance after installing your coil. I, as well as some others, disagree. In my opinion, you should only lock your resistance if your atty’s resistance tends to fluctuate (for whatever reason), or if you tend to vape in different temperatures (such as in an AC-controlled office, as well as out in the eyes of Hades aka South African sunshine) and you don’t have a built-in ambient temperature sensor in your mod. Regardless of my or anyone else’s opinions, lock or don’t lock your resistance based on what you feel works for you. Keep the following in mind though: the resistance of a coil takes a number of vapes to settle (and, quite often, only settles after leaving it overnight), and might even change a bit directly after a rewicking. So if you do lock your resistance shortly after a rebuild/rewick, just check the actual resistance a day later to see whether you need to adjust your (locked) resistance. In addition, if you feel that your vape isn’t the same at a given temperature two days in a row (especially near the end of a coil’s lifetime), then you might want to check the locked resistance again. Lastly, if you lock your resistance in order to get a more consistent temperature callibration throughout the day, try to measure and lock your resistance early in the morning, before you start vaping, and keep it locked for the day, but unlock and relock again the next morning. With all that said, I actually tend to lock the resistance of stock TC coils - I found these to sometimes fluctuate a bit.

TCR and TFR. I’ve already talked about the Temperature Coefficient of Resistance (TCR) - which is a single value describing the relationship between temperature and resistance of a wire in a linear fashion. If we want a more accurate description, we need to do so non-linearly. Although we can, in principle, use a mathematical fitting to get a decent non-linear curve, if we were to put that into a microchip on a mod we have to install a much more advanced microchip and firmware. An easier method is to have different linear curves describe different temperature ranges - these are known as Temperature Factors of Resistance (TFR). The only mods that uses these are DNA200 mods, as far as I know. Using TFR instead of TCR helps to give a smoother temperature curve (which can lead to less sudden drops in power), and more accurate and defined temperature ranges - you might get a bit more power in the lower ranges (120 to 150 °C) than a TCR-based mod, and more accuracy near the higher end of the spectrum. TFR curves are also helpful when using non-standard wire or funky TC builds. However, TCR is usually more than good enough for a decent TC vape. In fact, many people actually use TCR instead of TFR on a DNA200. TFR and how to use it will be discussed in a later part.

6. Styles of TC vaping

There are, generally speaking, three distinct ways of vaping in TC mode.

1) Temperature-protected mode. In principle, this is the same as non-TC / Power mode - we are hitting our atty with a specific wattage (effectively, by controlling the voltage), but temperature is measured. If a maximum temperature is reached, the power is reduced accordingly. However, the goal is to only climb towards the temperature, and if we were on our way to getting a dry hit (because of too long a puff, or too little juice left, or improper wicking) temp-protection kicks in and lowers the power the mod sends to the atty. In this manner, Temperature-protected mode is very similar to normal non-TC vaping, except with a very strong (and reliable) safety net.

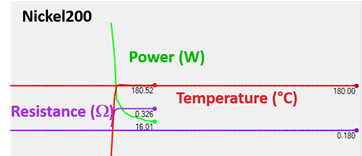

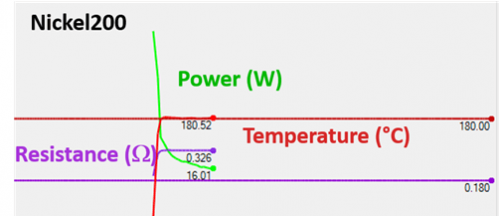

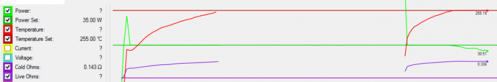

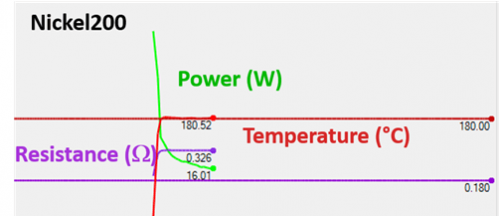

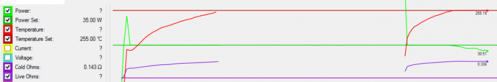

It looks like this:

Red is temperature, green is power, and purple is resistance. You will notice two puffs in the image. Both are running at 35W (although with a slightly higher hit in the first 0.5 seconds - I will get to this later). In the first puff, you can see constant power, and the temperature slowly climbing upwards. This is what a typical puff on a Kanthal build would look like if we could measure the internal temperature. In the second puff, after the atty is already warm (and probably on the verge of a dry hit), the temperature is still climbing upwards but once it hits a set limit (in this case, 255 °C), temp-protection kicks in and the power starts dropping from 35 W in order to keep the temperature from rising any further.

Running in this mode is great, as it vapes very much like a Kanthal build, but with less worry. You can also push up the power more than you might ordinarily do since even the slightest hint of a dry hit will send a resistance spike to your mod, which will trigger the temp-control. And finally, if your TFR isn’t 100% set up correctly, it is still ok since you don’t necessarily will be vaping much after you’ve hit the max temp. Personally, I run a Subtank Mini (Ni or Ti) in this mode, as I love normal non-TC Subtank vaping and just want the safety net.

Generally, you’ll pretty much disable pre-heat when vaping in this way, your power limit will be the same as when vaping in non-TC mode, and you’ll have a generally high temperature limit - which is (usually) present as a preventative measure that you don’t get dry hits, or that you prevent your vape from becoming hotter than you like it. To change the temperature of your vape in this mode, you change your power limit rather than the temperature limit - like you’d do in non-TC mode.

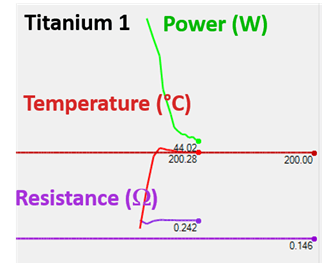

2) Temperature-controlled mode. Here, we are trying to get to a specific temperature as fast as possible, and keep it there. The goal is to get a very smooth vape, at one specific temperature (and all the flavours at that temperature), and, regardless of the airflow, puff-time or ambient temperature, just keep vaping on at the same level.

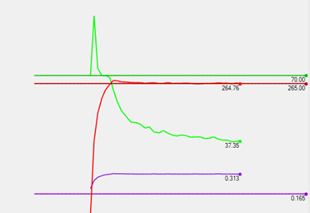

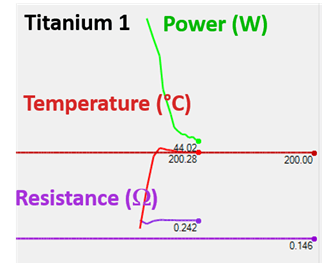

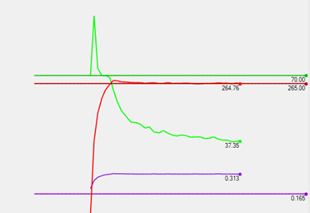

IT looks like this:

Again, red is temperature, green is power. Here, after an initial spike (which is as high and long as possible in order to get the temp quickly to a specific level, thanks to the pre-heat), the temperature remains constant (at 265 °C) while the power keeps dropping down slowly.

Running in this mode is the typical TC-mode which most people expect, and what was initially the gospel being spread to why TC is the future. However, in order to run an atty this way, you need: i) a well-calibrated TFR curve (more on that later), ii) well-built coils (no hot-spots, identical coils in multi-coil setup) and iii) an accurate resistance meter on your mod (DNA200 is pretty damn accurate, but not accurate enough to run stainless steel in this manner). The result is a very smooth vape, and usually looooong drags. But in practice, despite the rage about TC, I actually think vaping in this manner is not the best way in which we can. In a non-TC setup, your vape is heating up more and more with time during a puff. As a result, you get a) different flavours at different times (temperatures), all of which accumulates in your mouth and lungs, b) different throat hit at different times. The former is why some people say TC actually produces less complex flavours. In terms of throat hit, most people don’t like getting the throat hit (as well as heat, vapour and mouth-feel) which they usually get at the end of a puff right at the beginning, and as such, vapes at considerably lower temperatures - which then gives them the throat hit they get at the beginning of a non-TC vape right trough the entire puff, which is generally unsatisfactory.

Don’t get me wrong - sometimes vaping in this mode just hits the spot, especially if you just want to have a smooth, relaxing and no-fuss vape. In addition, it is very useful for DIYers in order to taste which flavours of your juice comes out at what temps.

I run my Aromamizer with dual Ti coils in this mode, since I’m anyway getting a smoother vape with vertical coils and the side-airflow, so this mode just enhances the quality of the vape.

To set it up, try to get a high pre-heat and a high power limit - generally about 1.25 to 1.5 times more than you usually vape at, although don’t make it too high so that you can avoid the ‘pop’ at a beginning of a vape. After you’ve set up your power limit, you don’t bother with it further, and you just adjust your temperature as you see fit.

3) Hybrid temp-regulated mode. The combination of numbers 1) and 2). The idea is to a) pre-heat your coil to a specific minimum temperature, b) vape at a specific wattage, with slowly increasing temperature for a wider flavour profile and a less-severe initial hit, and c) limit the temp for the last part of the vape, in order to prevent dry-hitting and too-hot vapour, while still giving a smooth but powerful final vape.

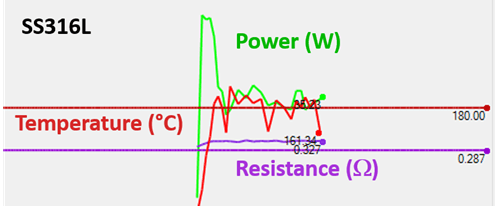

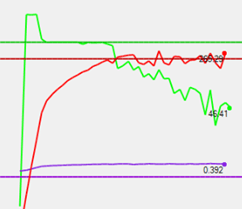

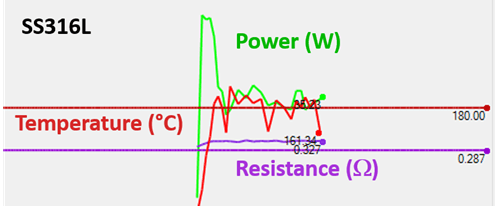

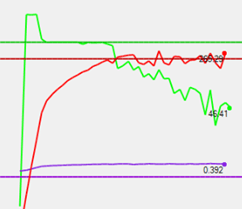

It looks like this:

Notice how the power (green line) initially spikes, after which it drops down to a certain level for a while, and then starts to gradually drop down to lower levels. The temperature on the other hand, has a large gradient initially, after which it climbs more-or-less linearly, and then finally fluctuates around a limited point. The fluctuation (spikiness) is an unfortunate result of using stainless steel wire, which has a very low temperature coeffiecient of resistivity (TCR) and won’t be seen for Titanium or Nickel. (More on how to reduce spikiness in a later Part)!

To set up your vape in this mode takes some playing around to get it juuuuuuuuust right, but it is very rewarding. Try to get the power limit which is nice for you - you don’t necessarily want it as high as possible, and can afford to have a slightly lower power limit than what you’ll usually vape at, since the pre-heat will make sure that you don’t have a sluggish ramp-up time. Next, try to figure out the temperature which you want your vape to end at and adjust the temperature accordingly. Lastly, play around with different pre-heat powers, timings and hardness in order to figure out the ramp up that is needed to get your coils going, but to still leave some room for them to heat up for the remainder of your puff.

While software like Escribe makes it really much, much easier to set up your TC vape in this manner, you can do it with any decent TC mod - it just takes some experimentation. Take a moderately complex juice and run it at different temperatures in temperature-controlled mode, and note what flavours you get at what temperatures. Then start to play around with the pre-heat, power and temp limits, and see if you can tweak it using TC variables so that every puff is just fantastic.

That’s it for Part 1. In the next part I’ll discuss more practical matters and examples on the finer points of TC vaping!

This is a work-in-progress guide to temperature control (TC) in the vaping domain – what it is exactly, how it works, how it is implemented in different mods, a description of all the variables of TC and how to tweak them in order to modify your vaping experience!

This guide is structured in the following manner:

PART 1. Introduction

1. Factors affecting vaping temperature

2. Temperature control basics: Coil temperature and resistance

3. TC-enabled Mods & Wires, a quick comparison

4. TC variables: Pre-heat punch, power, temperature limit, TCR and TFR

5. Styles of TC vaping

6. Links for more information

PART 2. Fine-tuning your vape

1. Deciding on your TC style, wire material and coil shape

2. Adjusting pre-heat, power and temperature

3. Adjusting linear TCR values

PART 3. Escribe and DNA200

1. What is Evolv, DNA200 and Escribe?

2. Visual tutorial to using Escribe

3. Diagnostics: Atomiser analyser, Device Monitor

4. Modifying TFR values

PART 4: Fixing common TC Problems

At this stage, only Part 1 is fully finished; I will add links to the relative post as I complete them. The old version of this guide was primarily an Escribe guide, and until I’ve finished updating it, it will remain as a separate post linked to Part 3.

I will also be using Escribe & the DNA200 chip to explain and illustrate most of the concepts covered in this guide. However, please realize that the same principles apply to most TC-enabled mods, and most of the capabilities of the DNA200 can be approximated in some way or the other in other chips – it is not necessary to go out and buy an expensive DNA200 mod just in order to apply some of the things covered in this guide. The DNA200 chip was primarily developed as a research tool, and therefore provides a very good diagnostic method to fully understand what is happening with TC vaping, and how to improve on it.

In addition to Escribe, I will be referring a lot to some of the predicted physical properties of a coil, which can be calculated through the excellent vaping calculator, www.steam-engine.org. If you haven’t looked at this website before, now is the time. I will not be going into the details of using this website, but I will be posting a lot of information which can be calculated there.

Lastly, please note that English is not my first language, and, for that matter, my language skills are quite horrible. I also have only a limited knowledge of the physics involved, so if you spot any mistakes, don’t be afraid to point them out! I am primarily a vaper with a tad too much curiosity, so most of what I describe is a result of my own conjectures and therefore should not be accepted as universal truths.

This guide is primarily written for beginners with little foreknowledge of the subject matter. However, I believe that those who have tinkered around with TC might still be able to pick up a thing or two, especially if they themselves have not yet played around with a DNA200 chip. Finally, this guide is written as a generalized overview of TC; unfortunately, not all TC mods work the same, or even use the same terminology - so you might have to use your own discretion to relate some of the information in this guide to your own mod. Alternatively, if you have a question on how the information in this guide relates to your own mod, don’t feel bad to ask about it - somebody somewhere will have the same mod as you and should be able to help!

PART 1. Introduction

1. Factors affecting vaping temperature

So you’ve heard of this temperature control thing. Maybe you’ve taken a toot on a friend’s mod, or your own mod can do TC, but beyond a little bit tinkering, you’ve never bothered to look too closely.

TC vaping is all about measuring and controlling the temperature of your coil as it heats up. What it is not is a direct control of the temperature of the actual vapour which you inhale. Therefore, before jumping into the nuts and bolts of TC vaping, let us discuss first some of the factors which affects the temperature of the final vape product. These factors can be divided into two groups: i) Coil factors and ii) atomizer factors. I will discuss the atomizer factors first:

a) Direct airflow. The amount of airflow you have on the atomizer itself is one of the primary factors of the temperature of your vape. A very large airflow (in other words, large or many holes on the side or bottom of your atomizer), coupled with a strong inhale, will result in a much cooler vape in comparison to the same coil and electrical power in an atomizer with less airflow.

b) Indirect airflow. Many atomizers have indirect airflow holes somewhere not on the coil (such as the drip-tip of the Smok TFV4 - which have controllable airflow at the top). This airflow will always cool the vapour you inhale, since it does not hit the heated coil in any way. It will also disperse the clouds and flavour to some extent - equivalent to keeping the side of your mouth open when vaping. However, it is a great way to cool down an otherwise too hot vape setup.

c) Internal airflow & chamber size. The size of the atomizer’s chamber (in other words, the area where your coil is actually located) have a very big impact on the temperature which you experience. This is in conjunction with the size of your coil, the position of your coil and the amount of cotton you stuff into the chamber. Generally though, larger chambers coupled with smaller coils will give you a cooler vape. However, it is possible to have an atomizer with a small chamber (such as a Goblin Mini or Subtank Mini) coupled with a sufficiently small coil to give a very cool vape. In addition to chamber size, the chamber shape is also important. Here, we have to use our imagination to some extent. The time which the air spends in the chamber is a primary factor of the temperature. If the incoming airflow hits the coil directly, but is blocked either by the size of the coil or the amount of wick, it will spend more time in the chamber and will consequently become hotter. On the other hand, if the incoming airflow only hits the side of the coil, and have a direct path to the chimney, the driptip and the mouth, it will spend considerably less time in the chamber and around the coil and, consequently, be a little bit cooler. In addition, the time which air spends in the chimney (in other words, in the absence of a heated coil) will allow more energy transfer between the air and the atomizer, and again, result in a slightly cooler vape. On aspect which should be mentioned here is the vortex effect. Some atomizers (especially drippers, but newer tanks - such as the Goblin Mini v2 - have this feature as well) have conical or grooved chimneys - which effectively swirls the air around inside the chamber. Usually, this vortex effect results in a slightly cooler vape (since the air spends more time inside the chamber) and slightly improved flavour. This effect works better in some atomizers than others, though.

d) Wicking. I’ve already mentioned that too much wick (especially outside the coil) can block the airflow and result in a hotter vape. Ironically, too little wick can cause the same effect, but for different reasons. This is all about the amount of juice which can be vaporized. Energy is spent by the coil in order to heat the juice - which is an endothermic effect and therefore lowers the temperature. If, however, the coil cannot effectively vaporize the juice and the excess heat of the coil is transferred to the air around it, as well as the atomizer, and results in a much hotter vape. When vapers complain that their atomizer (and vape) becomes very hot but without large clouds and/or flavour, this is usually the problem.

e) Heat capacity of the juice. The content of different juices heats up at a different rate, depending on the PG/VG ratio, the amount and composition of flavours and the nicotine concentration. This is determined by the partial heat capacity of each component – in other words, how much energy is absorbed by each component in order to raise the temperature (and eventually vaporize) of that component. High heat capacities leads to more energy required to vaporize it, and generally (for the same power) results in a cooler vape. This effect should be noticeable by many vapers - when you change the juice of a tank/dripper but nothing else and you suddenly get a warmer/cooler vape. I haven’t hunted down the exact heat capacities for each component, but I will probably do so in the near future for the sake of Science!

Next, and before we discuss the relevance of these factors with regards to TC, we will quickly discuss the coil properties and their influence on the final vaping temperature:

a) Power. The actual number and velocity of electrons (the current and potential difference, respectively, coupled with the resistance) flowing through the coil will obviously influence the heat of the coil the most. Higher power (in watts) will result in either more electrons or faster electrons moving through the coil, which results in more collisions through the coil, which results in higher energy and, finally, a higher temperature.

b) Coil resistance. The coil resistance is often misunderstood by many vapers. The resistance of a wire is what causes the actual energy increase when electricity is passed through it. However, a lower resistance will allow more electrons to be passed through the coil at a quicker rate (effectively, with more force), which actually results in a larger number of collisions between electrons and metal, which actually results in higher energy and temperature increase in the coil. This is more apparent when a mech mod is used, which has the same voltage in different coils, but because of a lower resistance in one coil, will result in a larger current draw, larger power and finally, higher temperature. With regulated mods, things change a bit, since the mod determines the voltage needed to reach a specified power with a given coil resistance. Generally, however, even in a regulated mod vapers testify that lower coil resistances gives more clouds at the same power output. The bottom line is that higher resistance coils will generally heat up quicker, but will hit a more or less max temperature than lower resistance (but slower heating) coils.

c) Heat flux and surface area. Here, we will ask the assistance of the wonderful www.steam-engine.org, which can calculate a predicted heat flux and surface area of a coil. The heat flux of a coil gives the power distribution per mm2 surface area, and is an indication of the amount of power needed to heat up a coil. A coil with a lower heat flux will therefore require much more power to heat up to the same temperature than a coil with a higher heat flux. Consequently, the heat of the coil (which is more or less correlated with the heat of the vape) with a low heat flux will be much lower at the same power than a coil with a higher heat flux. The heat flux is directly correlated with the surface area of the coil - a larger surface area will result in a lower heat flux. On the other hand, a larger surface area allows for more juice to be vaporized at the same time, as well as more air to pass over the saturated coil - which therefore results in more flavour and vapour. The result is that a coil with a lower heat flux can be vaped at higher power for the same coil temperature, which generally results in more flavour and larger clouds (if the airflow is sufficient). Steam-Engine actually has a very nice, qualitative feature which tells you how hot the vapour will be at a given power output.

In the above example (taken from Steam-engine), you can see that the coil on the left (a dual coil Kanthal 26 AWG) has a very high Heat flux of 277 mW/mm2 at 50 W, and steam-engine predicts that it will be quite a hot vape. On the other hand, the same general coil, only twisted, will have a much lower heat flux (69 mW/mm2 @ 50 W) and will be much cooler at the same power, as indicated by the little blue icon.

d) Heat capacity. Another property calculated by www.steam-engine.org, the heat capacity determines how much energy (directly related to power) is required to raise the temperature of the coil by 1 degree Kelvin. The heat capacity gives the ramp-up of a coil - in other words, the time required to heat up a coil at a given power output. Higher heat capacity results in a lagging coil (typical for Clapton coils) which will take some time to get to a decent vaping output.

In the example above, the non-twisted coil has a low heat capacity of 29.87 mJ/K (milli Joules per Kelvin - or energy per degree temperature), and will therefore heat up very quickly. The twisted coil, on the other hand, has a heat capacity of 119.49 mJ/K -about 4 times higher. This coil, despite being much cooler at higher wattages (as given by the heat flux), will take much longer to heat up due to the high heat capacity.

Lastly, the ambient temperature plays a very big effect in the temperature of your vape. Even though most TC mods can compensate for the ambient temperature of the wire, the temperature of the air going into your atomizer will determine a large amount of the final vape temperature. In other words, your atomizer and vape will generally heat up much faster on a hot day than a cold one.

The bottom line of this lengthy discussion is that the temperature of your vape is a result of many, interplaying factors. The biggest of these is the power given to the coil and the available airflow (both in terms of direct airflow and the size/shape of the coil inside). The take-away is that, even though we call TC vaping temperature controlled, TC really refers only to coil-temperature controlled. Your TC mod might read 250 °C, but the actual vapour temperature will definitely not be 250 °C, and what’s more, it will feel very different in different atomizers (or in the same atomizer but with different coil setups). I’ve actually once tried to calibrate all my atomizers to give the same perceived temperature for the same TC temp, but that turned out to be too big of a schlep. It is important to realize that while with TC vaping you can control to some extent the temperature of your vape, the biggest factor in the final temperature of your vape will still be determined when you build the coil or select an atomizer.

2. Why TC?

If the temperature of your inhaled vape is a result of many factors, why would anyone bother with TC then?

In the most elementary implementation, TC will give an upper limit to the temperature of the coil and prevent dry hits. This is nice for drippers, as you can continue vaping until your coils are effectively dry without having to experience increasingly dry hits. It is also nice for tanks, especially if the tank isn’t wicking wonderfully, and you can finish a tank completely before refilling with a new juice. In this implementation, you can also take longer and more consecutive draws of your atomizer without having to risk a dry hit.

However, TC can be used to better optimize your vape to suit your style. In normal non-TC power (or Kanthal) vaping, the only variables left for your control (after you’ve built your coils) are the power output and airflow control. TC adds a few additional variables which can be tinkered with in order to fine-tune your vape. On the one hand, it can be used to control coil builds which ramps up too quickly, in order to take longer draws at the desired vape temperature. It can also be used to control builds which ramps up too slowly, in order to reach the desired temperature as soon as possible. TC is especially useful for juice tasting, and especially for vaping complex juices which get the best distribution of flavours at a specific temperature, or if a specific juice has an undesired note at higher temperatures.

However, none-TC builds are still more user friendly in terms of pick-up-and-vape. TC really asks for some tinkering, playing around and curiosity towards your setup. You can use this guide to set your TC up in such a way as to just prevent dry hits or vape at a specific temperature, but you can also use this guide (in conjunction with some dedicated tinkering time) to really get a great vaping experience!

3. Temperature control basics: Coil temperature and resistance

TC is in principle a method rooted in calibration. A TC mod approximates the temperature of your coils, and adjusts the power output dynamically as needed: if the coil temperature reaches a maximum, the power is reduced accordingly in order to keep the temperature from rising further. If the coil temperature is too low, the power output is increased. The amount of control a mod has over the power output is dependent on how accurately it can measure the coil temperature, and how finely it can adjust the power output. Earlier and less advanced TC mods tends to have less finer control over the power output - once the coil temperature hits a limit, it drops the power too much and a noticeable drop in vapour production can immediately be experienced. More advanced TC mods, on the other hand, adjusts the power accordingly before the temperature limit has even been reached, and can minutely adjust the power in order to keep the coil temperature constant. The same applies for accuracy, which is generally more a factor of the coil material. Certain materials’ (such as Nickel) temperature can be approximated more accurately, which means the corresponding power adjustments can be improved to keep up with the changing temperature.

The biggest caveat to all of this is the fact that the coil temperature cannot be measured directly - a mod does not actually have a thermostat (or any advanced instrument for analysis) directly connected to the wire in order to measure the coil’s temperature. However, all metallic wires have a very useful intrinsic physical property: a coil’s resistance increases as it gets hot. Using this property, a relationship between temperature and resistance can be established. In other words, a mod only has to measure the change in the resistance of a coil (which even none-TC regulated mods do anyway), and through a mathematical relationship, it can estimate the temperature of the coil.

The relationship between temperature and resistance can be modelled in different (and generally of different levels of mathematical complexity) ways. The most basic way is linearly (in other words, through a single value) and is known as the Temperature Coefficient of Resistance (TCR). The TCR gives how many degrees of heat (which can be given in Kelvin, Celcius or Fahrenheit) a wire increases for each increment of change in resistance (in ohms). Each material has a specific TCR, and it doesn’t matter whether you have a single coil, a twisted coil or a clapton coil - the TCR remains the same. We use the same TCR for dual/tri/quad coils as well, although there is a bit of a debate regarding the accuracy of doing so.