That's against my beliefs. I use a brick!How many times have you used a spanner when in a pinch?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: this_feature_currently_requires_accessing_site_using_safari

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Weekend Projects

- Thread starter Resistance

- Start date

-

- Tags

- weekend

I was saving to buy a hammer. Every month I came to the shop with the cash, the price increased.

I eventually screwed that idea.View attachment 211407 I needed a scarce weight of 28oz. Not a size needed alot.

A tool is a mans best friend! My Grandfather used to be a tool and dye maker back in the day and that’s where I learned the phrase “ if you don’t have the right tool for the job, don’t do the job”

Sent from my iPhone using Tapatalk

A tool is a mans best friend! My Grandfather used to be a tool and dye maker back in the day and that’s where I learned the phrase “ if you don’t have the right tool for the job, don’t do the job”

Sent from my iPhone using Tapatalk

Indeed. R600 28oz hickory handle in the right hands is plenty good enough!

A few more tweaks and we can go full swing production

Awesome build!

Just finished my latest mod, been busy with it these last 2 weeks.

I was generously given a pcb and batt sled from a Vaporesso Gen by Hein from Juicy Joe's.

The 510 was shorting so I hacked the 510 from an IPV6X and built a box out of epoxy laminated denim.

The buttons are PLA from a 3D printer, I wanted SS but the reduction gearbox on my lathe broke and turning SS at 820 rpm isnt the way its done.

Have to admit Im quite impressed with all the onboard functions as well as the pc software dashboard.

I was generously given a pcb and batt sled from a Vaporesso Gen by Hein from Juicy Joe's.

The 510 was shorting so I hacked the 510 from an IPV6X and built a box out of epoxy laminated denim.

The buttons are PLA from a 3D printer, I wanted SS but the reduction gearbox on my lathe broke and turning SS at 820 rpm isnt the way its done.

Have to admit Im quite impressed with all the onboard functions as well as the pc software dashboard.

Just finished my latest mod, been busy with it these last 2 weeks.

I was generously given a pcb and batt sled from a Vaporesso Gen by Hein from Juicy Joe's.

The 510 was shorting so I hacked the 510 from an IPV6X and built a box out of epoxy laminated denim.

The buttons are PLA from a 3D printer, I wanted SS but the reduction gearbox on my lathe broke and turning SS at 820 rpm isnt the way its done.

Have to admit Im quite impressed with all the onboard functions as well as the pc software dashboard.

View attachment 214123

very well done Sir !

Excellent job!Just finished my latest mod, been busy with it these last 2 weeks.

I was generously given a pcb and batt sled from a Vaporesso Gen by Hein from Juicy Joe's.

The 510 was shorting so I hacked the 510 from an IPV6X and built a box out of epoxy laminated denim.

The buttons are PLA from a 3D printer, I wanted SS but the reduction gearbox on my lathe broke and turning SS at 820 rpm isnt the way its done.

Have to admit Im quite impressed with all the onboard functions as well as the pc software dashboard.

View attachment 214123

The buttons match the drip tip. Well done it's an awesome job and it will give you something to do next weekend , making new buttons.Just finished my latest mod, been busy with it these last 2 weeks.

I was generously given a pcb and batt sled from a Vaporesso Gen by Hein from Juicy Joe's.

The 510 was shorting so I hacked the 510 from an IPV6X and built a box out of epoxy laminated denim.

The buttons are PLA from a 3D printer, I wanted SS but the reduction gearbox on my lathe broke and turning SS at 820 rpm isnt the way its done.

Have to admit Im quite impressed with all the onboard functions as well as the pc software dashboard.

View attachment 214123

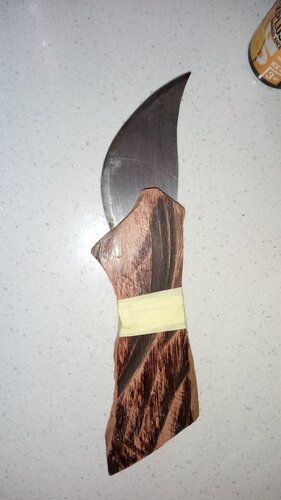

Aesthetically the top one looks good. Not much good at judging practicality as I don't use knives fo much else other than cutting my thumb and biltong.An extended weekend project that never seemed to happen.View attachment 214419 View attachment 214420

I'm trying to find a suitable blade position that will still deem it useful.

An extended weekend project that never seemed to happen.View attachment 214419 View attachment 214420

I'm trying to find a suitable blade position that will still deem it useful.

Looks great. I am with @Stew , the higher position, but with slightly deeper notches for both thumb on top and forefinger on the bottom maybe for better grip when handling it either way and not letting your fingers slip onto the blade with forward thrusting.

This was what I originally went for. The scales are still oversized and once glued and pinned I'll sand it to fit in the hand.Looks great. I am with @Stew , the higher position, but with slightly deeper notches for both thumb on top and forefinger on the bottom maybe for better grip when handling it either way and not letting your fingers slip onto the blade with forward thrusting.

View attachment 214421

I over thought it when I taped the scales in position.

I haven't done that in a while. I have used lime. For both successfully, but then again I was just experimenting.. I didn't turn pro!Finished up some pattern molding boxes and a babington burner and wondered if there are any metal casters on the forum.

Looking for moulding sand and parting powder.

View attachment 214424

Paste a link if you have an Instructable on the build. Your setup looks professionally made. Awesome!Finished up some pattern molding boxes and a babington burner and wondered if there are any metal casters on the forum.

Looking for moulding sand and parting powder.

View attachment 214424

Thanks.Paste a link if you have an Instructable on the build. Your setup looks professionally made. Awesome!

no Instructable, figured there were enough bab burners around so didnt want to rehash it.

The boxes I built after watching olfoundryman on youtube.

https://www.capewatch.co.za/product/delft-clay/Finished up some pattern molding boxes and a babington burner and wondered if there are any metal casters on the forum.

Looking for moulding sand and parting powder.

View attachment 214424

Read here talcum powder can be used.

You definitely have my interest in this. I'm def a taker when it's available.

Thanks for the vote, alas the product is not at what I'd call a commercial level.You definitely have my interest in this. I'm def a taker when it's available.

To be frank the juice did improve after 3 days, but one does get a very good idea in the first day.

We need to start production soon. I think three day steep is over enough. Who's taking orders. I'll run the Q.A.Thanks for the vote, alas the product is not at what I'd call a commercial level.

To be frank the juice did improve after 3 days, but one does get a very good idea in the first day.

Saw the first picture. Figured out it was sideways. Saw second picture. Thought what the heck is this. Saw third picture, LOL.View attachment 215198 View attachment 215199 View attachment 215197

Finished another project,but it needs tweaking birdie doesn't grip that we'll yet.

Similar threads

- Replies

- 0

- Views

- 188

- Replies

- 6

- Views

- 1K

- Replies

- 1

- Views

- 99