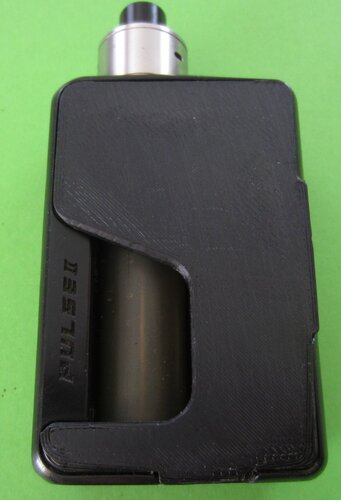

By basic I mean a plain 3mm thick door, no radius-ed or chamfered edges.

No magnet holes in the back either, but it should be easy enough to edit in Tinkercad.

I made mine in ABS 0.4mm layer height and 100% infill so I could sand and slice the plastic.

The door varies in thickness from 2.25mm on the edges to 3mm in the center.

The chamfer on the bottom is a variable width due to the curved doors, beyond my CAD abilities at the mo.

The one on the side is trickier because it starts from the door bottom surface, whereas cad programs will assume its an equal chamfer with a 45 degree angle, again beyond my skills at the mo.

So I just took a blade and sliced the plastic in line with the body. Sanded with 320 grit wet&dry and it looks fine to me.

tagging @YzeOne cos you were looking for V2 stls which Ive zipped and attached.

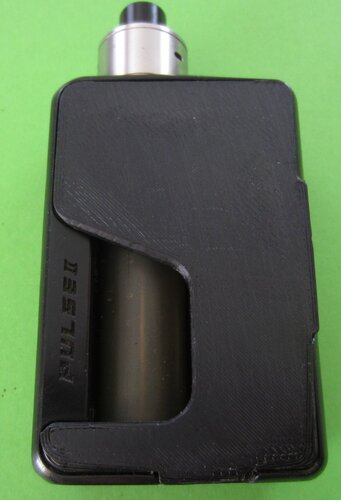

No magnet holes in the back either, but it should be easy enough to edit in Tinkercad.

I made mine in ABS 0.4mm layer height and 100% infill so I could sand and slice the plastic.

The door varies in thickness from 2.25mm on the edges to 3mm in the center.

The chamfer on the bottom is a variable width due to the curved doors, beyond my CAD abilities at the mo.

The one on the side is trickier because it starts from the door bottom surface, whereas cad programs will assume its an equal chamfer with a 45 degree angle, again beyond my skills at the mo.

So I just took a blade and sliced the plastic in line with the body. Sanded with 320 grit wet&dry and it looks fine to me.

tagging @YzeOne cos you were looking for V2 stls which Ive zipped and attached.