[FA]power-off[/FA]

Technical Wire Specifications - Cold formed

- 304 Stainless steel

- 22 Gauge ("0.0255 square)

- 0.89 Ohms per foot resistance

Features and Benefits:

- Extremely durable and long lasting material, Hard and crisp 90° edges

- Increased flavor and vapor due to increase of available surface area

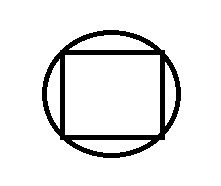

- Square cross section allows for multiple variations in coil wrapping technique

- Square cross section allows for single strands of wire to be twisted along their own axis

- Decreased ramp-up and cool-down time compared to wires and builds of similar resistance

Final Notes:

- We do not believe in hiding what is in our wire from anyone, the composition of our wire is the same material breakdown as 304 Stainless Steel that is used in the food service industry however the cold forming process changes the molecular structure slightly.

- After the cold forming is completed we heat treat the wire to remove some of the springiness so that packaging is possible, prior to heat treatment the wire is nearly impossible to coil into anything smaller than a 6" diameter!

**We do not have plans to bring anything other than this specific 22GA wire to market, due to the cold forming it is unbelievably difficult to deal with prior to heat treatment and is very difficult to keep from twisting as is, this would make a smaller wire much more labor intensive as it would be even harder to keep straight and much more costly to produce. Always remember to PLEASE USE CAUTION WHEN HANDLING as the wire ends are very sharp and the square shape provides a number of sharp points that can pierce skin, be mindful and use the appropriate tools to bend and hold the wire, please don't forget always wear safety goggles when cutting any wire!**

*ATTENTION - SQUAREOHM WIRE IS NOT FOR EVERYONE!*

- At 0.89 Ohms per foot it is specifically targeted at the "supersubohm" vaper, this is an extremely durable wire that can handle very high wattage for sustained periods of time. This makes it a great choice for cloud chasing and extremely high wattage builds. *Squareohm wire is only recommended for the experienced builder*

- Due to the increased mass of the square wire the resulting reduction in overall resistance facilitates the need for a larger coil to build to the same resistance as round 22GA Kanthal. Resistance wise, Squareohm wire is roughly equivalent to building with 20GA Kanthal however Squareohm wire takes up less space in the post holes while also maximizing surface area to create excellent flavor and vapor production.

Build Example:

- A dual coil set up with 2mm ID and 7 wraps each with 22GA standard round Kanthal would meter out to 0.12 to 0.15 ohms depending on leg length of the installed coils. You would need a 3mm coil ID and the same 7 wraps for each coil to get the same resistance with Squareohm wire because of the reduced overall resistance.

Note:

- For the best performance it is not recommended to build dual coil builds higher in resistance than 0.20 ohms or single coil builds above 0.40 ohms. This is due to the mass of the wire that is required to build coils above these resistances.

[FA]share[/FA]http://www.squareohm.com/