Not a damn.Thats the one who also used RIT dye. Another I watched was Warped Lab he seems to use RIT as well, which is about R550+ as an import and they dont stock/have available purple.

Caswell anodizing solutions are R1100+

Free is problem free

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: this_feature_currently_requires_accessing_site_using_safari

Not a damn.Thats the one who also used RIT dye. Another I watched was Warped Lab he seems to use RIT as well, which is about R550+ as an import and they dont stock/have available purple.

Caswell anodizing solutions are R1100+

Agree, or as cheap as possible.Not a damn.

Free is problem free

for my build I am toying wiht the idea of just going titanium and anodizing that.

or getting Demascus for it.

I know the prototype I am making on sunday the plan is to use alluminium but I was aiming to keep that normal silver colour bcause its more to get dimentions worked out.

the plan for my face plate is to make it longer than needed, then put the 510 hole into that, and give it a nice bend so the face plate goes over the top curve of the mod as one solid piece.

this weekend is more about order of opperations on a cheap block of wood, so when my stabalized blocks are ready end of March I know my planned steps will work correctly.

will be a DNA250C duel 18650, magnetic battery door, with the Face plate making sort of an L bracket shape to hold the board and the 510, heirloom fit into the wood.

Tried it as a last ditch, but wasnt the look I was going for, more of a dirty plum than purple.Just asking, what about a tinted epoxy resin coating? View attachment 299161

Big risk of chipping, wont be able to erase the machining marks inside all the holes and a 3mm thick plate would be quite fragile.why not just cast solid epoxy exactly the way you want it and machine it into a face plate?

I saw on the finished product in the other thread so I understand what you did with the screen portion is just cast, question is why not just cast the face plate, machine it, then cast the "screen" back in?

valid point.Big risk of chipping, wont be able to erase the machining marks inside all the holes and a 3mm thick plate would be quite fragile.

I've always loved wooden mods. Specially DIY ones. Got pics?my weekend project hit an ugly snag this weekend.

a small slip while cleaning up an edge lead to quite a bad break on my wood mod.

this has lead to a small redesign.

but honestly I think the current piece of wood needs to be scrapped. and I need to start over.

I am struggling to find the kind of wood I am looking for for this project. I keep going for pieces that are close to final dimension and that leads to problems.

unfortunately wiht the break there is no point in taking pics. it went from an amazing looking but not yet finished mod to a couple of pieces of scrapwood. and it was a stabalised redbush block I used.I've always loved wooden mods. Specially DIY ones. Got pics?

Yeah, would have liked a heat pad but with separation between the stir bar and rotor, the attractive force stopping the bar from crashing out is greatly reduced.that looks freaking awesome.

having just gotten my a mag stirrer myself its a complete game changer. but my big thing is the heating controll. being able to stir juice at a nice 65 degrees for 4 or so hours does about the same as the first 2 days of steeping on fruity jucies. you still want to steep but the steep time is a lot less

retile heating pad from takealot.Yeah, would have liked a heat pad but with separation between the stir bar and rotor, the attractive force stopping the bar from crashing out is greatly reduced.

Ive been bald for 30yrs so no hairdryer.How about heated air?

I got an idea and not to sure if itll work.View attachment 300207

Smalll 240V hairdryer. Not very fast and not much heat

the reptile heating pad would work brilliantly.Ive been bald for 30yrs so no hairdryer.

Like baxsteen said, those small graphite snake/lizard heat pads work okay, just slow at 7w.

But theres no localised heat area on the glass which might cause an issue with a glass beaker.

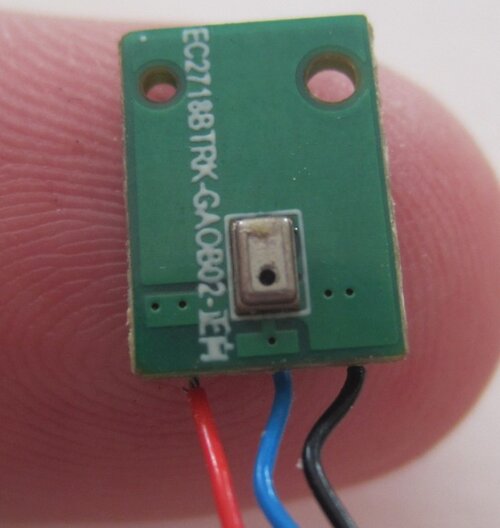

Got some of those auto draw switches if you'd like.Recently acquired a dead Bewolk Smart pod.

It had a dead vac switch which I havent seen anywhere else so had to route wires to the outside and glue on a micro switch for the fire button.

Been wondering what I could convert this touch screen 30W device into.

Only thing I can think of so far is to extend the housing and chuck in an 18650.

Its sized for a 16450 which is an odd size that I havent came across yet, but it seems like a lot of pt to do a redesign if it doesnt have a practical use case.

View attachment 300261

dead vac switch

View attachment 300262

I've got a ziplock full from dispo's that Ive parted out, but they're all the round 6mm dia can style and consequently wont fit into the 4.5mm dia housing meant for that tiny 1.8mmx2.5mm factory one.Got some of those auto draw switches if you'd like.