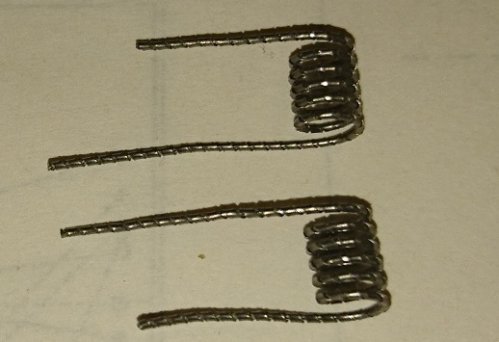

For the record, compressed coils have to be dry-burned to get rid of hot spots. Dry-burning expands the coil a little bit (not really noticeble), getting rid of hot-spots. Spaced coils generally don't have that problem. Any hot-spot on a coil with TC can wreck havoc. For that reason, compressed Ni coils are risky because you can't dry burn them, hence spaced.

I still haven't noticed big differences between spaced and compressed. It mostly depends on the airflow for me, and how many wraps I'm planning. For cyclops airflow (such as on Velocity) I like to do spaced, but for round or directed airflow (Kennedy style, Crius, or round, such as Aromamizer) I like to do compressed. Matching in this way gives me the best flavour. I also have had bad experiences with long compressed coils (9+ wraps, I would guess), especially with small IDs, in line with what @blujeenz said. However, I've had anaemic TC vapes with spaced coils as well, especially with fewer wraps.

I still haven't noticed big differences between spaced and compressed. It mostly depends on the airflow for me, and how many wraps I'm planning. For cyclops airflow (such as on Velocity) I like to do spaced, but for round or directed airflow (Kennedy style, Crius, or round, such as Aromamizer) I like to do compressed. Matching in this way gives me the best flavour. I also have had bad experiences with long compressed coils (9+ wraps, I would guess), especially with small IDs, in line with what @blujeenz said. However, I've had anaemic TC vapes with spaced coils as well, especially with fewer wraps.